Blog sull'automazione

Dall'ottimizzazione all'autonomia - Le cinque principali tendenze per l'automazione per il 2025 di OMRON

04 Gennaio 2025 Con l'approssimarsi del 2025, il mondo dell'automazione industriale si sta avvicinando a un nuovo capitolo. Secondo la teoria SINIC di OMRON, che collega i progressi tecnologici al cambiamento sociale, stiamo ora passando dalla "società dell'ottimizzazione" alla "società dell'autonomia".La teoria, creata nel 1970 dal fondatore di OMRON, Kazuma Tateishi, prevede futuri sviluppi sociali e tecnologici a favore dell'innovazione. Nella fase di "ottimizzazione", l'attenzione è stata rivolta al perfezionamento dei processi, all'aumento dell'efficienza e all'utilizzo della tecnologia per migliorare le operazioni. Ma la "società dell'autonomia" rappresenta un'era completamente nuova, in cui i sistemi non solo funzionano in modo efficiente, ma si contraddistinguono per autoregolazione, autoapprendimento e capacità decisionali indipendenti.

La tecnologia non deve essere fine a se stessa: cosa succede quando l'automazione industriale incontra l'eccellenza operativa

30 Novembre 2024 Negli ultimi anni abbiamo assistito a rapidi progressi tecnologici, con l'ascesa dell'intelligenza artificiale (IA) che si è affermata come tendenza chiave. In uno studio condotto tra i produttori di Regno Unito, Stati Uniti e Canada, il 70% ha dichiarato di aver implementato una qualche forma di IA nelle proprie operazioni, dando segno di un profondo impegno profuso nell'adozione di nuove tecnologie, sicuramente legato agli indiscutibili numerosi vantaggi dall'automazione.

Muovere i primi passi verso una digitalizzazione di successo

12 Novembre 2024 Costruire una fabbrica digitale non rappresenta di per sé un obiettivo finale o una motivazione. Una fabbrica digitale è uno strumento che offre alle aziende manifatturiere, che operano nel settore alimentare, della cura della persona, farmaceutico o automobilistico, la flessibilità necessaria per rispondere ai cambiamenti del mercato.

PPWR: perché la collaborazione tra catene, la tracciabilità e il packaging intelligente sono fondamentali

24 Settembre 2024 Secondo i dati Eurostat, nel 2021 ogni individuo residente nell'Unione europea ha prodotto 188,7 kg di imballaggi, quasi 32 kg in più rispetto al 2011. Da allora la quantità di scarti di imballaggi in plastica è aumentata del 27%. Nonostante l'incremento dei tassi di riciclaggio, un volume elevato di imballaggi di plastica non viene ancora destinato al riciclaggio: le statistiche più recenti indicano che solo una manciata di paesi europei è prossima a raggiungere un tasso di riciclaggio della plastica del 50%. Dal momento che il quadro giuridico esistente non è stato in grado di promuovere una riduzione degli scarti di imballaggio, nel 2022 la Commissione ha proposto una revisione della direttiva del 2018 del Regolamento sugli imballaggi e sui rifiuti di imballaggio (PPWR).Il PPWR rivisto dovrebbe entrare in vigore entro la fine di quest'anno e cambierà radicalmente il modo in cui l'imballaggio viene progettato, consumato e smaltito. Il regolamento aggiornato presenta un vasto ambito di applicazione, ma gli obiettivi fondamentali prevedono la riduzione della quantità di rifiuti di imballaggio generati e l'aumento della riciclabilità degli imballaggi.

Evitiamo ogni intralcio all'efficienza: perché le aziende non dovrebbero posticipare i loro piani in ambito di robotica?

24 Settembre 2024 Il ritardo degli investimenti in tecnologie innovative comporta numerosi rischi. Le aziende che sono ancora titubanti dovrebbero porsi tre domande.L'economia europea deve affrontare una serie di sfide che influiscono sulla sua crescita, stabilità e competitività. Il continente, ad esempio, conta una delle popolazioni più antiche del mondo, così che l'invecchiamento della forza lavoro aumenterà il carico sui sistemi di previdenza sociale e ridurrà la disponibilità di lavoratori, rallentando potenzialmente la crescita economica. Inoltre, l'impegno dell'UE verso il Green Deal e il raggiungimento della neutralità del carbonio entro il 2050 richiedono investimenti sostanziali e cambiamenti strutturali in vari settori. A ciò si aggiunge la mancanza di disponibilità a investire a causa dei timori finanziari. Un recente studio del McKinsey Global Institute (MGI) ha rilevato che le grandi aziende europee con un fatturato superiore a 1 miliardo di dollari sono rimaste indietro rispetto alle loro controparti statunitensi. Infatti, messe tutte insieme, queste aziende investono 400 miliardi di dollari all'anno in meno e crescono un terzo più lentamente.Questa difficoltà degli investimenti può tuttavia portare a diversi problemi con effetto sia sul breve che sul lungo termine, come svantaggi in termini di competitività, sostenibilità e reputazione, ma anche minore produttività e successo nell'attrarre nuovi lavoratori qualificati. In questo scenario, la robotica innovativa è in grado di contrastare tali sviluppi ma richiede anche finanziamenti ben ponderati. Pertanto, le aziende che attualmente limitano i propri investimenti dovrebbero chiedersi con urgenza se ciò non possa finire per ritorcersi contro di loro nel lungo termine. Per esaminare al meglio il dilemma, è essenziale porsi 3 domande:

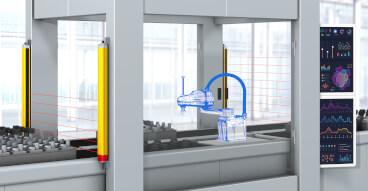

Digitalizzazione con standard aperti: la ricetta per la massima tranquillità

02 Settembre 2024 Possiamo trasformare le mie previsioni in realtà? Saremo in grado di rispettare le scadenze? Ho abbastanza informazioni per avere certezze? Come sta andando la fabbrica in termini di QCDE (vale a dire qualità, costi, tempi di consegna e impatto ambientale), rispetto ai nostri obiettivi e alla concorrenza? Queste sono alcune preoccupazioni che tengono svegli i dirigenti di fabbrica; preoccupazioni che possono essere risolte grazie alla digitalizzazione. In un ambiente di produzione digitalizzato, i dirigenti di fabbrica non devono preoccuparsi delle incognite, dei rischi e delle possibilità che questi si verifichino. La digitalizzazione elimina le incertezze e consente l'ottimizzazione basata sulle prestazioni. Fornisce informazioni utili per aiutare i responsabili di fabbrica a migliorare la qualità, ridurre i costi, accorciare i tempi di consegna e limitare l'impatto ambientale. Il responsabile di una fabbrica digitalizzata non dovrà svegliarsi preoccupato nel cuore della notte, ma se così fosse, basterà una rapida occhiata al cellulare per appurare che tutto funziona a dovere. Tuttavia, passare da uno stato di insonnia indotto dall'ansia a un sonno tranquillo non è facile. La digitalizzazione, infatti, può essere piuttosto noiosa. Raramente i responsabili dei progetti possono permettersi di lavorare su un foglio bianco; la maggior parte del tempo lavorano con una moltitudine di tecnologie obsolete, cercando di digitalizzare le linee di produzione che incorporano macchine che non hanno mai registrato dati e che sono state costruite prima ancora che esistessero i protocolli di comunicazione dati. Tutto ciò si traduce in una sfida importante per l'integrazione di OT e IT.

Rifornimento dinamico a bordo linea: una risposta strategica alle attuali sfide della produzione

15 Luglio 2024 Se i produttori vogliono rimanere efficienti e competitivi, affrontando al contempo le sfide poste dalla personalizzazione e dalla carenza di manodopera, è tempo di riconsiderare i sistemi e le pratiche di rifornimento a bordo linea. AMR e cobot potrebbero essere la risposta? La tendenza alla personalizzazione ha generato numerose sfide operative per i produttori. La necessità di ospitare una più ampia gamma di componenti e materiali introduce una variabilità che i sistemi tradizionali faticano a gestire in modo efficiente. Ciò può comportare costi di inventario maggiori, tempi di consegna più lunghi e ritardi nella produzione. I dati empirici sottolineano l'impatto della personalizzazione sulle operazioni di produzione; i produttori hanno dichiarato di aver dovuto affrontare tempi di consegna prolungati, costi di produzione più elevati e la necessità di gestire più inventari. Queste cifre illustrano le sfide tangibili poste dalla personalizzazione, che richiedono approcci innovativi per gestirne la complessità in modo efficiente.

Il trend dei robot nel 2024: applicazioni semplici e flessibili, essenziali per sviluppare il pieno potenziale

03 Luglio 2024 Supporti di carico, colleghi, membri di un team: il ruolo dei robot è cambiato radicalmente negli ultimi 70 anni. L'IA dà luogo a maggiori possibilità, ma gli esseri umani rimangono il fattore determinante. Robot o esseri umani: da chi dipenderà la produzione in futuro? Dal brevetto di George Devol del 1954 per un manipolatore programmabile, questa domanda ha scatenato il dibattito. Il robot Unimate di Devol ha rivoluzionato il settore eseguendo attività pericolose in tutta sicurezza e facendo presente che l'obiettivo non è l'antagonismo di robot ed esseri umani, ma piuttosto "robot + esseri umani = efficienza". Nel corso di 70 anni, le esigenze del settore si sono evolute per dare priorità a flessibilità, scalabilità, adattabilità e sostenibilità. I robot gestiscono attività che consentono agli operatori di concentrarsi su attività a valore aggiunto.

Uniamo i punti: automatizziamo le attività di alimentazione per un vantaggio competitivo

18 Giugno 2024 Gli sviluppi nel settore della robotica stanno facilitando la concezione di sistemi flessibili di alimentazione e movimentazione sul lato della linea in grado di migliorare la sicurezza, la produttività e la qualità, affrontando al contempo la carenza di manodopera. L'automazione industriale di solito inizia con i punti. Con ciò intendiamo gli impianti di grandi dimensioni che eseguono attività complesse e visibilmente a valore aggiunto, sia che si tratti di imballaggio a flusso, stampaggio a iniezione, imballaggio in blister, imbottigliamento, pallettizzazione o altri processi di produzione principali. Le linee che uniscono questi punti (sistemi di movimentazione, carico e alimentazione) tendono ad essere considerate secondarie, tanto che queste attività vengono spesso svolte manualmente. Affidarsi a un operatore addetto al carico delle materie prime sulla linea di produzione o all'alimentazione dei componenti nelle macchine potrebbe sembrare la scelta più semplice ed economica piuttosto che investire nell'automazione. Ma questa è una visione miope che non tiene conto dei numerosi vantaggi aziendali che l'alimentazione e la movimentazione automatizzate sul lato della linea possono offrire in termini di efficienza, qualità dei prodotti, scalabilità e salute & sicurezza. È inoltre una visione sempre più obsoleta, data la pressione che l'attuale crisi del lavoro sta esercitando sul settore manifatturiero.

Le 4 sfide principali che i produttori di veicoli elettrici devono affrontare nel loro percorso verso il raggiungimento di un futuro sostenibile

17 Giugno 2024 I veicoli elettrici (EV) sono passati da un mercato di nicchia a una grande forza industriale negli ultimi anni. A partire dal 2023, le auto elettriche rappresentano quasi un veicolo su cinque venduti, con un incremento delle vendite di 3,5 milioni di unità, un salto del 35% rispetto all'anno precedente, secondo il Global EV Outlook 2024 dell'AIE. Si prevede che questa impennata continuerà, con proiezioni che indicano che le vendite nei mercati emergenti supereranno 1 milione di unità nel 2024, segnando un aumento del 40% rispetto al 2023. I governi di tutto il mondo stanno spingendo per ridurre le emissioni di CO2, il che sta accelerando questo passaggio ai veicoli elettrici.Quindi, cosa significa questo per i produttori del settore automotive? In primo luogo, significa che devono orientarsi verso la progettazione e la produzione di flotte prevalentemente elettriche, una strada già iniziata da molti. In secondo luogo, significa costruire nuove linee di produzione e padroneggiare nuovi processi di fabbricazione, il che può rappresentare una sfida notevole.È qui che entra in gioco un partner affidabile per l'automazione. La partnership con un esperto dell'automazione può aiutare a gestire le complessità di questa transizione a livello di settore. Con un ampio portafoglio tecnologico, supporto globale e una profonda esperienza nel settore automotive, OMRON è pronta a guidare i produttori nel viaggio dell'elettrificazione.Questo articolo esaminerà le principali sfide del settore della produzione di veicoli elettrici e come la partnership con OMRON può fornire soluzioni efficaci:

Anche se funziona, bisogna metterci le mani

04 Aprile 2024 La produzione FMCG si fa più sostenibile grazie a una gestione energetica intelligente

Fatevi avanti, signore! Esplorate interessanti opportunità di carriera nell'automazione

01 Marzo 2024 Maryam Dolatabadi e Asunción Pastrana Costa sono esperte di automazione presso OMRON. Fanno appello alle ragazze e alle donne: "Fatevi avanti, questo settore ha impellente bisogno di voi!"

Dall'ottimizzazione all'autonomia - Le cinque principali tendenze per l'automazione per il 2025 di OMRON

04 Gennaio 2025 Con l'approssimarsi del 2025, il mondo dell'automazione industriale si sta avvicinando a un nuovo capitolo. Secondo la teoria SINIC di OMRON, che collega i progressi tecnologici al cambiamento sociale, stiamo ora passando dalla "società dell'ottimizzazione" alla "società dell'autonomia".La teoria, creata nel 1970 dal fondatore di OMRON, Kazuma Tateishi, prevede futuri sviluppi sociali e tecnologici a favore dell'innovazione. Nella fase di "ottimizzazione", l'attenzione è stata rivolta al perfezionamento dei processi, all'aumento dell'efficienza e all'utilizzo della tecnologia per migliorare le operazioni. Ma la "società dell'autonomia" rappresenta un'era completamente nuova, in cui i sistemi non solo funzionano in modo efficiente, ma si contraddistinguono per autoregolazione, autoapprendimento e capacità decisionali indipendenti.

L’automazione nel 2024: OMRON condivide 6 previsioni per il nuovo anno

13 Dicembre 2023 Gli sconvolgimenti degli ultimi anni ci hanno portati in una nuova era caratterizzata da forti rischi di natura geopolitica ed economica. Ciò ha spinto le aziende produttrici a ripensare i propri modelli di business in un’ottica di resilienza e flessibilità, oltre che a rivedere le proprie supply chain e relazioni globali. Parallelamente, la pressione per integrare i principi ESG nei processi decisionali sta aumentando rapidamente. Allo stesso tempo, intelligenza artificiale, data science, digital twin e tecnologie di rilevamento, monitoraggio e visione si confermano sempre più come elementi essenziali per lo sviluppo di soluzioni di controllo e automazione in grado di aiutare il comparto manifatturiero ad affrontare questa nuova realtà. In particolare, secondo OMRON, saranno sei le principali tendenze che influenzeranno e plasmeranno l'automazione industriale nel 2024 e oltre.

Potenziare la forza lavoro: l'approccio di OMRON allo sviluppo delle competenze nel settore manifatturiero europeo

06 Settembre 2023 Alla scoperta dell'impegno costante di OMRON nel coltivare le competenze che valorizzeranno la prossima generazione, mentre l'industria intraprende un viaggio di trasformazione per sbloccare il pieno potenziale della Quarta Rivoluzione Industriale (4IR) e che, allo stesso tempo, si muove con coraggio verso la Quinta Rivoluzione Industriale (5IR).Nelle aule del mondo accademico, nei consigli di amministrazione dei leader d'impresa più orientati al futuro e tra i politici più lungimiranti è in corso un fervente dibattito. Il tema è quello del passaggio dalla Quarta Rivoluzione Industriale, 4IR, o Industria 4.0, come viene chiamata, all'Industria 5.0, che cambierà il mondo in cui viviamo.Storicamente la rivoluzione industriale corrisponde alla prima era delle macchine, la seconda si caratterizza per l'introduzione dell'elettricità, la terza vede la diffusione dell'elettronica e la quarta si associa a Internet, come piattaforma. Ora stiamo entrando nella quinta era delle macchine, che mette in evidenza la collaborazione armoniosa uomo-macchina e il contributo dell'industria alla società. È questo il momento non solo di adattarsi, ma di guidare, di essere pionieri e di creare un futuro in cui l'innovazione non conosce limiti. Klaus Schwab, fondatore e presidente esecutivo del World Economic Forum, ha osservato che siamo sull'orlo di una rivoluzione tecnologica che cambierà radicalmente il nostro modo di vivere, lavorare e relazionarci. Nella sua scala, portata e complessità, la trasformazione sarà diversa da tutto quello che l'umanità abbia mai sperimentato prima. Il nostro mondo sta subendo una trasformazione. La produzione globale si sta evolvendo, guidata dall'automazione delle procedure industriali tradizionali attraverso la tecnologia intelligente, la comunicazione M2M e l'integrazione IoT. Questa sinergia alimenta un'automazione potenziata, una comunicazione perfetta e macchine intelligenti che analizzano e diagnosticano autonomamente le sfide.L'ascesa dell'intelligenza artificiale scatena dibattiti, alludendo a trasformazioni più profonde all'interno del nostro sistema sociale. Mentre attraversiamo questo scenario dinamico, ci prepariamo ad abbracciare l'innovazione e a rimodellare il nostro futuro.

Dai raggi X ai robot: OMRON festeggia 90 anni di innovazione

06 Giugno 2023 In occasione della Giornata del Fondatore, OMRON ha tracciato il ricordo dei suoi 90 anni di storia: in questi decenni, l'azienda si è spinta oltre i confini tecnologici e oggi confida in un futuro di innovazione dell'automazione basato su sostenibilità, digitalizzazione e collaborazione uomo-macchina.10 maggio: una data storica Il 10 maggio è probabilmente il giorno più importante del calendario OMRON. Ogni anno, in questo giorno, 30.000 dipendenti OMRON di tutto il mondo celebrano la vita e l'eredità del fondatore dell'azienda, Kazuma Tateishi. E lo fanno rinnovando il loro impegno verso la visione di Tateishi a favore dell'impiego della tecnologia per creare un mondo migliore, contribuendo al bene comune, spesso tramite la partecipazione a progetti di volontariato e beneficenza nelle proprie comunità. Traguardi nell'innovazione Il percorso di innovazione di OMRON è iniziato nel 1933 con lo sviluppo di un timer ad alta precisione per la fotografia a raggi X. Ciò ha segnato il primo contributo dell'azienda in risposta alle esigenze sociali. Nel 1960, OMRON ha presentato il primo interruttore di prossimità senza contatto al mondo, rivoluzionando le funzionalità avanzate di produzione di massa. Da allora, OMRON ha continuato a introdurre tecnologie all'avanguardia, tra cui il primo semaforo automatico, il sistema di stazioni ferroviarie senza equipaggio, il misuratore della pressione sanguigna indossabile, il controllore in logica fuzzy ultraveloce e le apparecchiature diagnostiche automatiche per cellule tumorali.

L'intelligenza artificiale (IA) nei sistemi robotici è in grado di gestire le parti relative alla sicurezza funzionale?

13 Aprile 2023 Autori: Josep Plassa, Safety Product Marketing Manager presso OMRON Europe e Atsushi Oshiro, Manager presso il Centro di sviluppo OMRONRobot e sistemi IA sono diventati parte integrante dei siti di produzione industriale. Per garantire la sicurezza degli operatori durante l'uso dei robot, è necessaria una valutazione dei rischi dettagliata. Tale valutazione viene eseguita dal punto di vista della sicurezza funzionale, che esamina i cinque elementi principali utilizzati dai robot per determinare le azioni di controllo autonomo: riconoscimento ambientale, pianificazione delle azioni, generazione della traiettoria, motion control e misurazione.

Intelligenza artificiale: macchine sempre più smart

08 Febbraio 2023 Dieci anni fa ero molto orgoglioso di quanto fossero smart le macchine della nostra azienda. Ora, a fronte della definizione odierna di "smart", mi rendo conto che in realtà erano piuttosto stupide.Perché? Perché anche se stavano svolgendo la funzione per cui erano state progettate, nel momento in cui incontravano un imprevisto o un evento fuori dall'ordinario si paralizzavano. Ed erano costrette a chiedere all'operatore "qual è il mio problema?".La risoluzione dei problemi e il ripristino del funzionamento delle macchine richiedeva l'intervento di persone intelligenti. Operatori altamente qualificati. Ingegneri software e hardware esperti. Il problema è che negli ultimi dieci anni questi professionisti sono diventati sempre più introvabili. Il numero di nuovi talenti in entrata nel settore non è sufficiente a compensare il numero di lavoratori in età pensionabile. Quando lasciano l'azienda, i pensionati portano con sé la propria conoscenza duramente maturata sul campo, risultato di anni di esperienza. Per ogni lavoratore in uscita, le aziende devono fare i conti con la prospettiva di una forza lavoro meno produttiva e meno qualificata.

La strada verso emissioni nette zero: strategie e tattiche

01 Febbraio 2023 La chiave per delineare un futuro a emissioni nette zero nella produzione sta trasformando la catena del valore - e passa attraverso l'automazione.Nel giugno 2022, New Scientist ha rilevato che un terzo delle principali aziende del mondo aveva obiettivi di emissioni nette zero, un aumento notevole rispetto allo stesso periodo dell'anno precedente.Sebbene questa tendenza sia senz'altro positiva, l'articolo riporta però che le modalità con cui le aziende pianificano di raggiungere le emissioni nette zero restano ancora lacunose.Il che non è esattamente una sorpresa. La creazione e l'implementazione di una strategia di emissioni nette zero è un'impresa titanica per qualsiasi azienda, in particolare con l'80% delle emissioni di gas serra appartenenti all'ambito 3, ossia le emissioni che si verificano a monte o a valle della catena del valore. Si tratta di una sfida particolare per le aziende FMCG, le cui catene di fornitura e la progressiva logistica sono lunghe e complesse.La maggior parte di queste aziende sa cosa occorre fare: decarbonizzare e promuovere la circolarità della catena del valore. Inoltre, tali aziende hanno una strategia per farlo, che in genere include: utilizzo ottimizzato di risorse ed energia, sostituzione di prodotti e processi a elevate emissioni ed eliminazione degli sprechi.Ma tradurre l'intenzione in azione è la sfida principale, ed è qui che l'automazione svolge un ruolo fondamentale.La raccolta e l'analisi dei dati sono essenziali per la transizione alle emissioni nette zero: altrimenti, in quale altro modo le aziende potrebbero sapere qual è il punto di partenza, dove devono migliorare, se sono effettivamente migliorate e di quanto? Dati affidabili sono la base per trasformare un impegno in un reale cambiamento e per comunicare in modo convincente e sicuro con gli stakeholder, rispettando gli obiettivi legati al clima.

Superare la crisi dell'energia e del carburante con l'automazione

07 Dicembre 2022 Per contrastare l'aumento dei prezzi e raggiungere gli obiettivi ambientali, le imprese industriali dovrebbero valutare come le tecnologie di automazione provenienti da un unico fornitore possano contribuire alla loro strategia di sostenibilità.I prezzi elevati di energia e carburante stanno mettendo a dura prova sia le famiglie, sia l'industria. Non solo la situazione influisce negativamente sui piani finanziari e sui portafogli, ma i prezzi eccessivi costringono alcune aziende a cessare la produzione. Secondo Make UK, il 42% dei produttori intervistati ha dichiarato che le bollette dell'elettricità sono aumentate del 100% negli ultimi 12 mesi e il 32% ha dichiarato che i prezzi del gas sono aumentati di oltre il 100% nell’ultimo anno. Un preoccupante 12% dei produttori ha già tagliato i posti di lavoro come conseguenza diretta dell'aumento delle bollette energetiche.La guerra in Ucraina, la pandemia di Covid-19 e i prezzi del gas sono solo alcune delle cause della crisi, che colpisce tutti i settori e ha un impatto su tutto, dai prezzi dell'energia alle catene di fornitura. Cosa dovrebbero prendere in considerazione ora le aziende manifatturiere? Strategie di automazione complete sono essenziali per una maggiore flessibilità ed efficienza energetica, come ad esempio robotica innovativa abbinata a sensori e tecnologie di visione, nonché all'intelligenza artificiale (Edge AI). Inoltre, i dati in tempo reale provenienti dagli impianti di produzione possono aiutare a rilevare le anomalie e a migliorare l'efficienza totale di un impianto (OEE, Overall Equipment Effectiveness).

Che direzione prenderà il futuro, l'intralogistica? Consigli per una maggiore efficienza

15 Novembre 2022 A volte ci concentriamo così tanto sul quadro generale che dimentichiamo aspetti meno vistosi eppure molto importanti che caratterizzano la produzione intelligente. Un esempio è l'intralogistica, ossia i flussi di materiali e merci che si svolgono presso le sedi di un'azienda o in un locale di produzione. Secondo quanto emerge da un recente studio , oltre l'80% delle aziende intervistate ritiene che un maggiore utilizzo dell'intelligenza artificiale e dell'automazione nell'intralogistica sia necessario per affrontare sfide come la carenza di lavoratori qualificati o i piani di crescita.Le aziende del settore automotive che desiderano soddisfare i requisiti del mercato e dei clienti, aumentare l'efficienza e diventare più sostenibili devono sviluppare nuove idee, e i costi energetici, la crisi del gas e l'aumento dell'inflazione rendono l'impresa ancora più ardua. I concetti di Smart Factory che combinano automazione innovativa, digitalizzazione e approcci intelligenti all'intralogistica possono fornire un prezioso supporto. In questo contesto, alcuni parlano di "Industry 4.0", altri di "fabbrica del futuro", altri ancora di Industrial Internet of Things (IIoT). Tuttavia, indipendentemente dal termine utilizzato, la cosa più importante è darsi subito da fare e cercare partner affidabili. L'intralogistica è un buon punto di partenza per dare avvio al cambiamento in poco tempo. Tale urgenza è legata al fatto che numerose aziende sono al momento fortemente limitate a causa della carenza di lavoratori qualificati. Le tecnologie moderne, come i robot mobili, offrono una valida soluzione.

In che modo l'ispezione IA adattiva può contribuire alla produzione flessibile?

04 Ottobre 2022 destinati ai magazzini, i produttori devono creare articoli personalizzati destinati ai consumatori stessi. Questo scenario sta rivoluzionando la produzione e spingendo le aziende a rivedere i loro processi. Allo stesso tempo, è diventato indispensabile eliminare del tutto reclami e, quindi, difetti.L'occhio allenato di un ispettore esperto è in grado di individuare rapidamente gli errori, ma un'attività di routine come questa è faticosa e non può essere eseguita ad ogni fase della produzione, soprattutto a causa delle attuali carenze di manodopera che investono diversi settori. Ma questa attività potrebbe essere automatizzata anche nella produzione a volumi ridotti e altamente diversificati? Un sistema di visione intelligente o un "occhio elettronico" potrebbe replicare l'immagine dell'occhio umano, con il vantaggio aggiuntivo della ripetibilità e della resistenza? L'ispezione adattiva più recente con IA può superare le sfide dell'ispezione automatizzata della qualità, con livelli più elevati di flessibilità, produttività e adattabilità.

Intelligenza artificiale: speranza, hype e FOMO

22 Settembre 2022 Dieci anni fa, quando ricevevamo richieste di informazioni su progetti basati sull'intelligenza artificiale, erano principalmente spinte dall'hype o dal FOMO. Quando chiedevo perché fossero interessati all'intelligenza artificiale, la risposta spesso era "perché il mio capo me l'ha chiesto", "perché possediamo molti dati" o "perché sembra un argomento interessante". Nessuno di questi era un motivo particolarmente valido e certamente non giustificava il forte investimento che le applicazioni AI avrebbero richiesto in quel momento.La situazione sta cambiando e, anziché l'hype o il "FOMO", è la speranza il fattore trainante. I clienti non chiedono più se possiamo aiutarli con l'intelligenza artificiale. Bensì se possiamo aiutarli con la manutenzione predittiva, il controllo della qualità o l'ottimizzazione dei processi. Si presentano con un problema che sperano possiamo risolvere. L'adozione dell'intelligenza artificiale non è più un obiettivo in sé. Al contrario, l'intelligenza artificiale è diventata un "fattore abilitante".Indipendentemente dal settore, che sia alimentare, farmaceutico, elettronico o automotive, l'obiettivo finale è lo stesso: produrre prodotti di alta qualità, privi di difetti a un costo inferiore, utilizzando meno energia e meno manodopera. L'intelligenza artificiale può essere una di una serie di soluzioni per raggiungere tali obiettivi.

L'automazione si adatta al packaging sostenibile

16 Agosto 2022 Hai mai ordinato online un articolo di piccole dimensioni per poi infuriarti vedendolo arrivare in una scatola oversize con pluriball, cuscini riempiti d'aria o inserti di carta?

Rifornimento dinamico a bordo linea: una risposta strategica alle attuali sfide della produzione

15 Luglio 2024 Se i produttori vogliono rimanere efficienti e competitivi, affrontando al contempo le sfide poste dalla personalizzazione e dalla carenza di manodopera, è tempo di riconsiderare i sistemi e le pratiche di rifornimento a bordo linea. AMR e cobot potrebbero essere la risposta? La tendenza alla personalizzazione ha generato numerose sfide operative per i produttori. La necessità di ospitare una più ampia gamma di componenti e materiali introduce una variabilità che i sistemi tradizionali faticano a gestire in modo efficiente. Ciò può comportare costi di inventario maggiori, tempi di consegna più lunghi e ritardi nella produzione. I dati empirici sottolineano l'impatto della personalizzazione sulle operazioni di produzione; i produttori hanno dichiarato di aver dovuto affrontare tempi di consegna prolungati, costi di produzione più elevati e la necessità di gestire più inventari. Queste cifre illustrano le sfide tangibili poste dalla personalizzazione, che richiedono approcci innovativi per gestirne la complessità in modo efficiente.

Il trend dei robot nel 2024: applicazioni semplici e flessibili, essenziali per sviluppare il pieno potenziale

03 Luglio 2024 Supporti di carico, colleghi, membri di un team: il ruolo dei robot è cambiato radicalmente negli ultimi 70 anni. L'IA dà luogo a maggiori possibilità, ma gli esseri umani rimangono il fattore determinante. Robot o esseri umani: da chi dipenderà la produzione in futuro? Dal brevetto di George Devol del 1954 per un manipolatore programmabile, questa domanda ha scatenato il dibattito. Il robot Unimate di Devol ha rivoluzionato il settore eseguendo attività pericolose in tutta sicurezza e facendo presente che l'obiettivo non è l'antagonismo di robot ed esseri umani, ma piuttosto "robot + esseri umani = efficienza". Nel corso di 70 anni, le esigenze del settore si sono evolute per dare priorità a flessibilità, scalabilità, adattabilità e sostenibilità. I robot gestiscono attività che consentono agli operatori di concentrarsi su attività a valore aggiunto.

Uniamo i punti: automatizziamo le attività di alimentazione per un vantaggio competitivo

18 Giugno 2024 Gli sviluppi nel settore della robotica stanno facilitando la concezione di sistemi flessibili di alimentazione e movimentazione sul lato della linea in grado di migliorare la sicurezza, la produttività e la qualità, affrontando al contempo la carenza di manodopera. L'automazione industriale di solito inizia con i punti. Con ciò intendiamo gli impianti di grandi dimensioni che eseguono attività complesse e visibilmente a valore aggiunto, sia che si tratti di imballaggio a flusso, stampaggio a iniezione, imballaggio in blister, imbottigliamento, pallettizzazione o altri processi di produzione principali. Le linee che uniscono questi punti (sistemi di movimentazione, carico e alimentazione) tendono ad essere considerate secondarie, tanto che queste attività vengono spesso svolte manualmente. Affidarsi a un operatore addetto al carico delle materie prime sulla linea di produzione o all'alimentazione dei componenti nelle macchine potrebbe sembrare la scelta più semplice ed economica piuttosto che investire nell'automazione. Ma questa è una visione miope che non tiene conto dei numerosi vantaggi aziendali che l'alimentazione e la movimentazione automatizzate sul lato della linea possono offrire in termini di efficienza, qualità dei prodotti, scalabilità e salute & sicurezza. È inoltre una visione sempre più obsoleta, data la pressione che l'attuale crisi del lavoro sta esercitando sul settore manifatturiero.

Abbracciare il cambiamento: analisi del processo di produzione flessibile

30 Gennaio 2024 Il mercato dei beni di consumo in rapida evoluzione sta attraversando una trasformazione guidata da fattori quali l'empowerment dei consumatori, le esigenze di personalizzazione, le preferenze salutiste, il veganismo, le preoccupazioni etiche e la sostenibilità. Ci aspettiamo che subirà più cambiamenti nel prossimo decennio che nei 50 anni precedenti, il che richiederà l'adattamento delle catene di produzione e distribuzione per soddisfare le tendenze emergenti. Il futuro delle fabbriche di beni di consumo in rapida evoluzione vedrà probabilmente l'impiego di strutture più piccole e intelligenti con circolazione autonoma dei beni e sistemi interconnessi.Le macchine, indipendenti o interconnesse, devono essere più flessibili che mai per garantire la fornitura tempestiva di materiali e imballaggi appropriati. La produzione deve essere più agile e sempre più incentrata su modelli pronti per la vendita al dettaglio con un approccio high mix-low volume con zero richiami. La domanda è: come raggiungere questo obiettivo con un costo minimo e un ROI rapido?

L’automazione nel 2024: OMRON condivide 6 previsioni per il nuovo anno

13 Dicembre 2023 Gli sconvolgimenti degli ultimi anni ci hanno portati in una nuova era caratterizzata da forti rischi di natura geopolitica ed economica. Ciò ha spinto le aziende produttrici a ripensare i propri modelli di business in un’ottica di resilienza e flessibilità, oltre che a rivedere le proprie supply chain e relazioni globali. Parallelamente, la pressione per integrare i principi ESG nei processi decisionali sta aumentando rapidamente. Allo stesso tempo, intelligenza artificiale, data science, digital twin e tecnologie di rilevamento, monitoraggio e visione si confermano sempre più come elementi essenziali per lo sviluppo di soluzioni di controllo e automazione in grado di aiutare il comparto manifatturiero ad affrontare questa nuova realtà. In particolare, secondo OMRON, saranno sei le principali tendenze che influenzeranno e plasmeranno l'automazione industriale nel 2024 e oltre.

Le quattro principali strategie per affrontare la carenza di manodopera con l'automazione

06 Settembre 2023 L'automazione è uno strumento per supportare la forza lavoro manuale e non per sostituirlaIn tutto il mondo, nel settore manifatturiero si rileva una carenza di manodopera sempre più preoccupante. Nonostante l'adozione di contromisure come gli incentivi finanziari e le specializzazioni per i lavoratori, sono necessarie soluzioni più innovative. Molti produttori scelgono di automatizzare le attività ripetitive, ma questo costituisce effettivamente un supporto per la forza lavoro attuale o un tentativo di sostituirla completamente?Nel 2023 Reuters ha rivelato una tendenza allarmante: il 53% delle aziende fatica a trovare il personale necessario. Questa carenza di manodopera, che si aggiunge all'aumento dei costi energetici e alla necessità di raggiungere gli obiettivi di emissioni zero, sta creando nuove sfide. Per riuscire a progredire garantendo una produzione sostenibile, le imprese devono adottare strategie innovative che consentano di colmare le carenze di manodopera e potenziare le capacità della forza lavoro attuale.Vediamo quindi quali sono le quattro strategie principali per gestire la carenza di manodopera e supportare la forza lavoro attraverso l'automazione:

L'automazione nel 2023: le 5 previsioni principali di OMRON Europe

01 Febbraio 2023 Alle porte di un nuovo anno, con tutte le opportunità che ne deriveranno, desidero evidenziare alcune delle principali tendenze che influenzeranno l'automazione industriale nel 2023 e oltre. Le industrie manifatturiere continueranno ad affrontare molte sfide e superarle richiederà maggiori resilienza e flessibilità nei modelli di business. Allo stesso tempo, le aziende devono adottare le tecnologie emergenti (rilevamento, robotica, 5G e intelligenza artificiale) in grado di risolvere i problemi legati alle sfide sociali.

Riders of the storm: affrontare l'incertezza economica trasformando le sfide sociali in opportunità tecnologiche

06 Dicembre 2022 Una delle domande che mi vengono spesso poste è quale sia la nostra strategia, in qualità di azienda di automazione industriale, per mantenere una crescita stabile in un'economia globale volatile e sempre più imprevedibile. La mia risposta, come potete immaginare, non si riduce a una frase, sebbene sia radicata in un unico concetto: SINIC. SINIC è l'acronimo di "Seed-Innovation to Need-Impetus Cyclic Evolution" ed è una teoria sviluppata dal fondatore di OMRON, il Dott. Kazuma Tateisi, nel 1970. Secondo questa filosofia, la scienza, la tecnologia e la società condividono un rapporto ciclico, e si influenzano reciprocamente. Le scoperte scientifiche aiutano la società a progredire e le esigenze sociali stimolano lo sviluppo tecnologico. OMRON Europe ha sempre seguito questa filosofia e nel corso dell'ultimo decennio ha gettato le basi per la creazione di soluzioni a valore aggiunto per le sfide sociali ed economiche attuali.

Quattro suggerimenti di automazione per le PMI

25 Novembre 2022 I leader aziendali di tutto il mondo devono affrontare una sfida dopo l'altra: oltre all'impennata dei costi causata dalla crisi energetica, vi sono problemi nella supply chain, carenza di lavoratori qualificati, requisiti di sostenibilità e problemi di digitalizzazione in continuo aumento. In particolare, le piccole e medie imprese (PMI) devono trovare rapidamente il modo per affrontare questi ostacoli. L'automazione offre una soluzione tramite la robotica, ad esempio cobot e AMR (robot mobili autonomi), nonché sensori, visori e intelligenza artificiale. Sebbene le aziende siano ben consapevoli dei vantaggi di tali tecnologie, alcuni studi dimostrano anche che molte di esse rimangono scettiche rispetto al loro utilizzo effettivo.In particolare, le aziende senza esperienza nel settore temono che l'uso dei robot possa portare con sé costi elevati. A questo scopo, in caso di dubbi sull'effettiva utilità dell'acquisto di un robot collaborativo o mobile per l'azienda, il nuovo calcolatore dei ROI di OMRON è in grado di fornire una rapida panoramica del ritorno sull'investimento e mostrare quando un investimento nella robotica coprirà i costi sostenuti.

Digitalizzazione nel settore automotive: sette suggerimenti per una produzione intelligente

02 Novembre 2022 Per aumentare la produttività e gestire al meglio le crisi, occorre essere smart dal punto di vista digitale, e questo vale anche per l'importante settore automotive. Non esiste altro modo se non quello di utilizzare gli strumenti digitali per soddisfare le esigenze dei clienti o gli obiettivi di produttività. L'intelligenza artificiale (IA) e la sostenibilità sono fattori e tematiche chiave, come dimostrato da uno studio condotto da Capgemini. Gli esperti di Gartner sottolineano l'importanza degli approcci di collaborazione open-source, degli ecosistemi olistici e delle partnership tecnologiche. Ma cosa dovremmo cercare nella digitalizzazione e nell'intralogistica nella produzione del futuro? Vogliamo suddividere la risposta a questa domanda in due parti, partendo da alcuni suggerimenti sulla digitalizzazione nella fabbrica intelligente. In qualità di esperto di automazione, OMRON supporta da molti anni i produttori e i fornitori per una digitalizzazione più sofisticata.

Flexible Manufacturing Roadshow: la fabbrica del futuro in giro per l'Europa

16 Giugno 2022 E se fosse possibile vedere, sentire e toccare la fabbrica del futuro? Cosa serve per ottenere una produzione flessibile, efficiente e sostenibile? Questa è l'idea di partenza dell'esclusivo Flexible Manufacturing Roadshow di OMRON che si terrà quest'anno in tutta Europa. Il roadshow prevede dimostrazioni esclusive di soluzioni collaborative uomo-macchina che non si possono osservare solitamente al di fuori di una fabbrica a causa delle loro dimensioni e della loro portata.

Costruire insieme la fabbrica del futuro

16 Giugno 2022 In qualità di una delle più grandi unità aziendali di OMRON, puntiamo a sviluppare ulteriormente lo stabilimento di Den Bosch per soddisfare le esigenze della regione EMEA.

Dall'ottimizzazione all'autonomia - Le cinque principali tendenze per l'automazione per il 2025 di OMRON

04 Gennaio 2025 Con l'approssimarsi del 2025, il mondo dell'automazione industriale si sta avvicinando a un nuovo capitolo. Secondo la teoria SINIC di OMRON, che collega i progressi tecnologici al cambiamento sociale, stiamo ora passando dalla "società dell'ottimizzazione" alla "società dell'autonomia".La teoria, creata nel 1970 dal fondatore di OMRON, Kazuma Tateishi, prevede futuri sviluppi sociali e tecnologici a favore dell'innovazione. Nella fase di "ottimizzazione", l'attenzione è stata rivolta al perfezionamento dei processi, all'aumento dell'efficienza e all'utilizzo della tecnologia per migliorare le operazioni. Ma la "società dell'autonomia" rappresenta un'era completamente nuova, in cui i sistemi non solo funzionano in modo efficiente, ma si contraddistinguono per autoregolazione, autoapprendimento e capacità decisionali indipendenti.

Muovere i primi passi verso una digitalizzazione di successo

12 Novembre 2024 Costruire una fabbrica digitale non rappresenta di per sé un obiettivo finale o una motivazione. Una fabbrica digitale è uno strumento che offre alle aziende manifatturiere, che operano nel settore alimentare, della cura della persona, farmaceutico o automobilistico, la flessibilità necessaria per rispondere ai cambiamenti del mercato.

Digitalizzazione con standard aperti: la ricetta per la massima tranquillità

02 Settembre 2024 Possiamo trasformare le mie previsioni in realtà? Saremo in grado di rispettare le scadenze? Ho abbastanza informazioni per avere certezze? Come sta andando la fabbrica in termini di QCDE (vale a dire qualità, costi, tempi di consegna e impatto ambientale), rispetto ai nostri obiettivi e alla concorrenza? Queste sono alcune preoccupazioni che tengono svegli i dirigenti di fabbrica; preoccupazioni che possono essere risolte grazie alla digitalizzazione. In un ambiente di produzione digitalizzato, i dirigenti di fabbrica non devono preoccuparsi delle incognite, dei rischi e delle possibilità che questi si verifichino. La digitalizzazione elimina le incertezze e consente l'ottimizzazione basata sulle prestazioni. Fornisce informazioni utili per aiutare i responsabili di fabbrica a migliorare la qualità, ridurre i costi, accorciare i tempi di consegna e limitare l'impatto ambientale. Il responsabile di una fabbrica digitalizzata non dovrà svegliarsi preoccupato nel cuore della notte, ma se così fosse, basterà una rapida occhiata al cellulare per appurare che tutto funziona a dovere. Tuttavia, passare da uno stato di insonnia indotto dall'ansia a un sonno tranquillo non è facile. La digitalizzazione, infatti, può essere piuttosto noiosa. Raramente i responsabili dei progetti possono permettersi di lavorare su un foglio bianco; la maggior parte del tempo lavorano con una moltitudine di tecnologie obsolete, cercando di digitalizzare le linee di produzione che incorporano macchine che non hanno mai registrato dati e che sono state costruite prima ancora che esistessero i protocolli di comunicazione dati. Tutto ciò si traduce in una sfida importante per l'integrazione di OT e IT.

Il trend dei robot nel 2024: applicazioni semplici e flessibili, essenziali per sviluppare il pieno potenziale

03 Luglio 2024 Supporti di carico, colleghi, membri di un team: il ruolo dei robot è cambiato radicalmente negli ultimi 70 anni. L'IA dà luogo a maggiori possibilità, ma gli esseri umani rimangono il fattore determinante. Robot o esseri umani: da chi dipenderà la produzione in futuro? Dal brevetto di George Devol del 1954 per un manipolatore programmabile, questa domanda ha scatenato il dibattito. Il robot Unimate di Devol ha rivoluzionato il settore eseguendo attività pericolose in tutta sicurezza e facendo presente che l'obiettivo non è l'antagonismo di robot ed esseri umani, ma piuttosto "robot + esseri umani = efficienza". Nel corso di 70 anni, le esigenze del settore si sono evolute per dare priorità a flessibilità, scalabilità, adattabilità e sostenibilità. I robot gestiscono attività che consentono agli operatori di concentrarsi su attività a valore aggiunto.

L’automazione nel 2024: OMRON condivide 6 previsioni per il nuovo anno

13 Dicembre 2023 Gli sconvolgimenti degli ultimi anni ci hanno portati in una nuova era caratterizzata da forti rischi di natura geopolitica ed economica. Ciò ha spinto le aziende produttrici a ripensare i propri modelli di business in un’ottica di resilienza e flessibilità, oltre che a rivedere le proprie supply chain e relazioni globali. Parallelamente, la pressione per integrare i principi ESG nei processi decisionali sta aumentando rapidamente. Allo stesso tempo, intelligenza artificiale, data science, digital twin e tecnologie di rilevamento, monitoraggio e visione si confermano sempre più come elementi essenziali per lo sviluppo di soluzioni di controllo e automazione in grado di aiutare il comparto manifatturiero ad affrontare questa nuova realtà. In particolare, secondo OMRON, saranno sei le principali tendenze che influenzeranno e plasmeranno l'automazione industriale nel 2024 e oltre.

Il passaggio ai veicoli elettrici si fa semplice: le tre sfide principali da superare nell'industria automotive

23 Novembre 2023 Il passaggio ai veicoli elettrici rappresenta un percorso impegnativo per i produttori automobilistici. Aziende consolidate che da sempre producono veicoli con motori a combustione si stanno avventurando in un mondo completamente nuovo di piattaforme per veicoli. Esaminiamo le principali sfide che il settore della produzione di veicoli elettrici deve affrontare ed esploriamo le più recenti soluzioni innovative che si prospettano.

Incontro di due mondi: convergenza fra IT e OT nell'automazione industriale

22 Settembre 2023 Un divario che deve essere colmato se si vuole trasformare la visione di oggi per le fabbriche del futuro nella realtà del domani. I produttori all'avanguardia stanno esplorando attentamente le opportunità offerte dalla trasformazione digitale per avvicinarsi ai propri ideali di produzione flessibile, efficiente e sostenibile. Tuttavia, a mano a mano che l'interesse per la digitalizzazione aumenta, diventa evidente che esista un enorme divario tra il mondo OT (Operational Technology) e quello IT (Information Technology). Un divario che deve essere colmato se si vuole trasformare la visione attuale delle fabbriche del futuro nella realtà di domani. Prima di esaminare il motivo per cui è necessaria una convergenza fra IT e OT, e capire come possiamo ottenerla, occorre tornare alle nozioni di base e chiarire alcuni malintesi a livello di terminologia.

Potenziare la forza lavoro: l'approccio di OMRON allo sviluppo delle competenze nel settore manifatturiero europeo

06 Settembre 2023 Alla scoperta dell'impegno costante di OMRON nel coltivare le competenze che valorizzeranno la prossima generazione, mentre l'industria intraprende un viaggio di trasformazione per sbloccare il pieno potenziale della Quarta Rivoluzione Industriale (4IR) e che, allo stesso tempo, si muove con coraggio verso la Quinta Rivoluzione Industriale (5IR).Nelle aule del mondo accademico, nei consigli di amministrazione dei leader d'impresa più orientati al futuro e tra i politici più lungimiranti è in corso un fervente dibattito. Il tema è quello del passaggio dalla Quarta Rivoluzione Industriale, 4IR, o Industria 4.0, come viene chiamata, all'Industria 5.0, che cambierà il mondo in cui viviamo.Storicamente la rivoluzione industriale corrisponde alla prima era delle macchine, la seconda si caratterizza per l'introduzione dell'elettricità, la terza vede la diffusione dell'elettronica e la quarta si associa a Internet, come piattaforma. Ora stiamo entrando nella quinta era delle macchine, che mette in evidenza la collaborazione armoniosa uomo-macchina e il contributo dell'industria alla società. È questo il momento non solo di adattarsi, ma di guidare, di essere pionieri e di creare un futuro in cui l'innovazione non conosce limiti. Klaus Schwab, fondatore e presidente esecutivo del World Economic Forum, ha osservato che siamo sull'orlo di una rivoluzione tecnologica che cambierà radicalmente il nostro modo di vivere, lavorare e relazionarci. Nella sua scala, portata e complessità, la trasformazione sarà diversa da tutto quello che l'umanità abbia mai sperimentato prima. Il nostro mondo sta subendo una trasformazione. La produzione globale si sta evolvendo, guidata dall'automazione delle procedure industriali tradizionali attraverso la tecnologia intelligente, la comunicazione M2M e l'integrazione IoT. Questa sinergia alimenta un'automazione potenziata, una comunicazione perfetta e macchine intelligenti che analizzano e diagnosticano autonomamente le sfide.L'ascesa dell'intelligenza artificiale scatena dibattiti, alludendo a trasformazioni più profonde all'interno del nostro sistema sociale. Mentre attraversiamo questo scenario dinamico, ci prepariamo ad abbracciare l'innovazione e a rimodellare il nostro futuro.

Dai raggi X ai robot: OMRON festeggia 90 anni di innovazione

06 Giugno 2023 In occasione della Giornata del Fondatore, OMRON ha tracciato il ricordo dei suoi 90 anni di storia: in questi decenni, l'azienda si è spinta oltre i confini tecnologici e oggi confida in un futuro di innovazione dell'automazione basato su sostenibilità, digitalizzazione e collaborazione uomo-macchina.10 maggio: una data storica Il 10 maggio è probabilmente il giorno più importante del calendario OMRON. Ogni anno, in questo giorno, 30.000 dipendenti OMRON di tutto il mondo celebrano la vita e l'eredità del fondatore dell'azienda, Kazuma Tateishi. E lo fanno rinnovando il loro impegno verso la visione di Tateishi a favore dell'impiego della tecnologia per creare un mondo migliore, contribuendo al bene comune, spesso tramite la partecipazione a progetti di volontariato e beneficenza nelle proprie comunità. Traguardi nell'innovazione Il percorso di innovazione di OMRON è iniziato nel 1933 con lo sviluppo di un timer ad alta precisione per la fotografia a raggi X. Ciò ha segnato il primo contributo dell'azienda in risposta alle esigenze sociali. Nel 1960, OMRON ha presentato il primo interruttore di prossimità senza contatto al mondo, rivoluzionando le funzionalità avanzate di produzione di massa. Da allora, OMRON ha continuato a introdurre tecnologie all'avanguardia, tra cui il primo semaforo automatico, il sistema di stazioni ferroviarie senza equipaggio, il misuratore della pressione sanguigna indossabile, il controllore in logica fuzzy ultraveloce e le apparecchiature diagnostiche automatiche per cellule tumorali.

Intelligenza artificiale: macchine sempre più smart

08 Febbraio 2023 Dieci anni fa ero molto orgoglioso di quanto fossero smart le macchine della nostra azienda. Ora, a fronte della definizione odierna di "smart", mi rendo conto che in realtà erano piuttosto stupide.Perché? Perché anche se stavano svolgendo la funzione per cui erano state progettate, nel momento in cui incontravano un imprevisto o un evento fuori dall'ordinario si paralizzavano. Ed erano costrette a chiedere all'operatore "qual è il mio problema?".La risoluzione dei problemi e il ripristino del funzionamento delle macchine richiedeva l'intervento di persone intelligenti. Operatori altamente qualificati. Ingegneri software e hardware esperti. Il problema è che negli ultimi dieci anni questi professionisti sono diventati sempre più introvabili. Il numero di nuovi talenti in entrata nel settore non è sufficiente a compensare il numero di lavoratori in età pensionabile. Quando lasciano l'azienda, i pensionati portano con sé la propria conoscenza duramente maturata sul campo, risultato di anni di esperienza. Per ogni lavoratore in uscita, le aziende devono fare i conti con la prospettiva di una forza lavoro meno produttiva e meno qualificata.

La strada verso emissioni nette zero: strategie e tattiche

01 Febbraio 2023 La chiave per delineare un futuro a emissioni nette zero nella produzione sta trasformando la catena del valore - e passa attraverso l'automazione.Nel giugno 2022, New Scientist ha rilevato che un terzo delle principali aziende del mondo aveva obiettivi di emissioni nette zero, un aumento notevole rispetto allo stesso periodo dell'anno precedente.Sebbene questa tendenza sia senz'altro positiva, l'articolo riporta però che le modalità con cui le aziende pianificano di raggiungere le emissioni nette zero restano ancora lacunose.Il che non è esattamente una sorpresa. La creazione e l'implementazione di una strategia di emissioni nette zero è un'impresa titanica per qualsiasi azienda, in particolare con l'80% delle emissioni di gas serra appartenenti all'ambito 3, ossia le emissioni che si verificano a monte o a valle della catena del valore. Si tratta di una sfida particolare per le aziende FMCG, le cui catene di fornitura e la progressiva logistica sono lunghe e complesse.La maggior parte di queste aziende sa cosa occorre fare: decarbonizzare e promuovere la circolarità della catena del valore. Inoltre, tali aziende hanno una strategia per farlo, che in genere include: utilizzo ottimizzato di risorse ed energia, sostituzione di prodotti e processi a elevate emissioni ed eliminazione degli sprechi.Ma tradurre l'intenzione in azione è la sfida principale, ed è qui che l'automazione svolge un ruolo fondamentale.La raccolta e l'analisi dei dati sono essenziali per la transizione alle emissioni nette zero: altrimenti, in quale altro modo le aziende potrebbero sapere qual è il punto di partenza, dove devono migliorare, se sono effettivamente migliorate e di quanto? Dati affidabili sono la base per trasformare un impegno in un reale cambiamento e per comunicare in modo convincente e sicuro con gli stakeholder, rispettando gli obiettivi legati al clima.

Superare la crisi dell'energia e del carburante con l'automazione

07 Dicembre 2022 Per contrastare l'aumento dei prezzi e raggiungere gli obiettivi ambientali, le imprese industriali dovrebbero valutare come le tecnologie di automazione provenienti da un unico fornitore possano contribuire alla loro strategia di sostenibilità.I prezzi elevati di energia e carburante stanno mettendo a dura prova sia le famiglie, sia l'industria. Non solo la situazione influisce negativamente sui piani finanziari e sui portafogli, ma i prezzi eccessivi costringono alcune aziende a cessare la produzione. Secondo Make UK, il 42% dei produttori intervistati ha dichiarato che le bollette dell'elettricità sono aumentate del 100% negli ultimi 12 mesi e il 32% ha dichiarato che i prezzi del gas sono aumentati di oltre il 100% nell’ultimo anno. Un preoccupante 12% dei produttori ha già tagliato i posti di lavoro come conseguenza diretta dell'aumento delle bollette energetiche.La guerra in Ucraina, la pandemia di Covid-19 e i prezzi del gas sono solo alcune delle cause della crisi, che colpisce tutti i settori e ha un impatto su tutto, dai prezzi dell'energia alle catene di fornitura. Cosa dovrebbero prendere in considerazione ora le aziende manifatturiere? Strategie di automazione complete sono essenziali per una maggiore flessibilità ed efficienza energetica, come ad esempio robotica innovativa abbinata a sensori e tecnologie di visione, nonché all'intelligenza artificiale (Edge AI). Inoltre, i dati in tempo reale provenienti dagli impianti di produzione possono aiutare a rilevare le anomalie e a migliorare l'efficienza totale di un impianto (OEE, Overall Equipment Effectiveness).

Perché i sistemi di ispezione automatizzati sono fondamentali per la produzione di veicoli elettrici

23 Marzo 2023 La preoccupazione per la sicurezza prevale di gran lunga su tutte le altre motivazioni di apprensione nel settore automobilistico e la produzione di veicoli elettrici non fa eccezione. Tuttavia, la sicurezza può anche implicare complessità che nei veicoli moderni, in particolare elettrici, è tale da spingere i produttori a non affidarsi più ai tradizionali metodi di ispezione basati su campioni o verifiche.

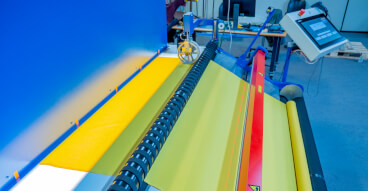

Vadain automatizza l'ispezione dei tessuti per tende con la visione artificiale

08 Aprile 2022 Vadain, leader nel mercato delle tende personalizzate nei Paesi Bassi, aveva bisogno di una soluzione in grado di rilevare gli errori nei tempi più brevi possibile in chilometri di tessuti per tende. Insieme agli sviluppatori di software di Sycade, alla tecnologia di visione artificiale OMRON e al costruttore di macchine Eisenkolb, hanno sviluppato una soluzione automatizzata capace di rilevare e analizzare gli errori nei tessuti per tende, lasciandosi alle spalle il processo di ispezione manuale, molto dispendioso in termini di tempo.

Automazione industriale: quattro suggerimenti per il futuro della produzione F&B

16 Luglio 2020 La pandemia di coronavirus ha posto grandi sfide alle organizzazioni di tutti i tipi e dimensioni. Nell'industria alimentare e dei beni di consumo, le aziende si sono trovate ad affrontare una significativa riduzione dei consumi e interruzioni delle catene di fornitura e, mentre il consumo casalingo ha registrato un aumento, il consumo esterno all'ambito domestico ha praticamente subito una battuta d'arresto. Ma in che modo i produttori possono adattare le proprie strategie aziendali e i processi di produzione in base alle esigenze odierne e sul lungo termine? La pandemia offre l'opportunità di rivedere processi e procedure obsoleti e di potenziarli con concetti quali robotica innovativa, tecnologia di rilevamento e strategie di automazione olistiche.

Six challenges for brand protection

19 Novembre 2019 Brand protection is an important topic for any business. But as industrial companies invest in new technology, such as smart robotics, artificial intelligence and vision systems, are they aware of the key challenges that could affect their brand?

Legacy of machine vision

16 Ottobre 2019 Did you know that for more than 40 years, Omron has developed vision sensing technologies for factory automation, surveillance and transport systems, and more recently for facial recognition and image processing for mobile phones, and even driver monitoring for autonomous driving?

Late-stage customization in pharmaceutical manufacturing

16 Ottobre 2019 As a result of serialization legislation, pharmaceutical manufacturers must now ensure that labels printed at a late stage contain all of the data required for compliance. This includes customizing product labels for certain markets, customers or products by adding variable data to labels or packaging. This avoids the need to stock individual packaging materials for each variant.

How to secure FMCG supply chains with traceability?

02 Ottobre 2019 The traceability of food and drink products throughout the production and distribution process can be a complex issue. For example, alcoholic drink producers need systems that enable them to comply with local regulations regarding food traceability, as well as tax legislation.

Barcodes: keeping track of product quality

02 Ottobre 2019 For many years, barcode technology has proved to be an economical and flexible identification technology. It has continued to develop and as a result, 1D and 2D codes (such as Datamatrix) are now used almost universally. Their versatility have made them a popular choice for streamlining many key supply chain processes, including production, logistics and item traceability.

Is your production line ready for inspection?

12 Settembre 2019 Quality inspections are a critical requirement for all manufacturing and packaging lines. Being able to identify defective products before they are shipped to customers can bring significant savings in both time and money. It prevents costly product recalls, wasted production and potentially expensive legal costs.For perishable products – from food to pharmaceuticals – quality inspection of the packaging is also vital. An unreadable barcode or a wrong expiry date could lead to perfectly good products being discarded. And increasingly strict legislation is making clear marking a top priority for all types of products.

La tecnologia non deve essere fine a se stessa: cosa succede quando l'automazione industriale incontra l'eccellenza operativa

30 Novembre 2024 Negli ultimi anni abbiamo assistito a rapidi progressi tecnologici, con l'ascesa dell'intelligenza artificiale (IA) che si è affermata come tendenza chiave. In uno studio condotto tra i produttori di Regno Unito, Stati Uniti e Canada, il 70% ha dichiarato di aver implementato una qualche forma di IA nelle proprie operazioni, dando segno di un profondo impegno profuso nell'adozione di nuove tecnologie, sicuramente legato agli indiscutibili numerosi vantaggi dall'automazione.

Muovere i primi passi verso una digitalizzazione di successo

12 Novembre 2024 Costruire una fabbrica digitale non rappresenta di per sé un obiettivo finale o una motivazione. Una fabbrica digitale è uno strumento che offre alle aziende manifatturiere, che operano nel settore alimentare, della cura della persona, farmaceutico o automobilistico, la flessibilità necessaria per rispondere ai cambiamenti del mercato.

Evitiamo ogni intralcio all'efficienza: perché le aziende non dovrebbero posticipare i loro piani in ambito di robotica?

24 Settembre 2024 Il ritardo degli investimenti in tecnologie innovative comporta numerosi rischi. Le aziende che sono ancora titubanti dovrebbero porsi tre domande.L'economia europea deve affrontare una serie di sfide che influiscono sulla sua crescita, stabilità e competitività. Il continente, ad esempio, conta una delle popolazioni più antiche del mondo, così che l'invecchiamento della forza lavoro aumenterà il carico sui sistemi di previdenza sociale e ridurrà la disponibilità di lavoratori, rallentando potenzialmente la crescita economica. Inoltre, l'impegno dell'UE verso il Green Deal e il raggiungimento della neutralità del carbonio entro il 2050 richiedono investimenti sostanziali e cambiamenti strutturali in vari settori. A ciò si aggiunge la mancanza di disponibilità a investire a causa dei timori finanziari. Un recente studio del McKinsey Global Institute (MGI) ha rilevato che le grandi aziende europee con un fatturato superiore a 1 miliardo di dollari sono rimaste indietro rispetto alle loro controparti statunitensi. Infatti, messe tutte insieme, queste aziende investono 400 miliardi di dollari all'anno in meno e crescono un terzo più lentamente.Questa difficoltà degli investimenti può tuttavia portare a diversi problemi con effetto sia sul breve che sul lungo termine, come svantaggi in termini di competitività, sostenibilità e reputazione, ma anche minore produttività e successo nell'attrarre nuovi lavoratori qualificati. In questo scenario, la robotica innovativa è in grado di contrastare tali sviluppi ma richiede anche finanziamenti ben ponderati. Pertanto, le aziende che attualmente limitano i propri investimenti dovrebbero chiedersi con urgenza se ciò non possa finire per ritorcersi contro di loro nel lungo termine. Per esaminare al meglio il dilemma, è essenziale porsi 3 domande:

Digitalizzazione con standard aperti: la ricetta per la massima tranquillità

02 Settembre 2024 Possiamo trasformare le mie previsioni in realtà? Saremo in grado di rispettare le scadenze? Ho abbastanza informazioni per avere certezze? Come sta andando la fabbrica in termini di QCDE (vale a dire qualità, costi, tempi di consegna e impatto ambientale), rispetto ai nostri obiettivi e alla concorrenza? Queste sono alcune preoccupazioni che tengono svegli i dirigenti di fabbrica; preoccupazioni che possono essere risolte grazie alla digitalizzazione. In un ambiente di produzione digitalizzato, i dirigenti di fabbrica non devono preoccuparsi delle incognite, dei rischi e delle possibilità che questi si verifichino. La digitalizzazione elimina le incertezze e consente l'ottimizzazione basata sulle prestazioni. Fornisce informazioni utili per aiutare i responsabili di fabbrica a migliorare la qualità, ridurre i costi, accorciare i tempi di consegna e limitare l'impatto ambientale. Il responsabile di una fabbrica digitalizzata non dovrà svegliarsi preoccupato nel cuore della notte, ma se così fosse, basterà una rapida occhiata al cellulare per appurare che tutto funziona a dovere. Tuttavia, passare da uno stato di insonnia indotto dall'ansia a un sonno tranquillo non è facile. La digitalizzazione, infatti, può essere piuttosto noiosa. Raramente i responsabili dei progetti possono permettersi di lavorare su un foglio bianco; la maggior parte del tempo lavorano con una moltitudine di tecnologie obsolete, cercando di digitalizzare le linee di produzione che incorporano macchine che non hanno mai registrato dati e che sono state costruite prima ancora che esistessero i protocolli di comunicazione dati. Tutto ciò si traduce in una sfida importante per l'integrazione di OT e IT.

L’automazione nel 2024: OMRON condivide 6 previsioni per il nuovo anno

13 Dicembre 2023 Gli sconvolgimenti degli ultimi anni ci hanno portati in una nuova era caratterizzata da forti rischi di natura geopolitica ed economica. Ciò ha spinto le aziende produttrici a ripensare i propri modelli di business in un’ottica di resilienza e flessibilità, oltre che a rivedere le proprie supply chain e relazioni globali. Parallelamente, la pressione per integrare i principi ESG nei processi decisionali sta aumentando rapidamente. Allo stesso tempo, intelligenza artificiale, data science, digital twin e tecnologie di rilevamento, monitoraggio e visione si confermano sempre più come elementi essenziali per lo sviluppo di soluzioni di controllo e automazione in grado di aiutare il comparto manifatturiero ad affrontare questa nuova realtà. In particolare, secondo OMRON, saranno sei le principali tendenze che influenzeranno e plasmeranno l'automazione industriale nel 2024 e oltre.

Incontro di due mondi: convergenza fra IT e OT nell'automazione industriale

22 Settembre 2023 Un divario che deve essere colmato se si vuole trasformare la visione di oggi per le fabbriche del futuro nella realtà del domani. I produttori all'avanguardia stanno esplorando attentamente le opportunità offerte dalla trasformazione digitale per avvicinarsi ai propri ideali di produzione flessibile, efficiente e sostenibile. Tuttavia, a mano a mano che l'interesse per la digitalizzazione aumenta, diventa evidente che esista un enorme divario tra il mondo OT (Operational Technology) e quello IT (Information Technology). Un divario che deve essere colmato se si vuole trasformare la visione attuale delle fabbriche del futuro nella realtà di domani. Prima di esaminare il motivo per cui è necessaria una convergenza fra IT e OT, e capire come possiamo ottenerla, occorre tornare alle nozioni di base e chiarire alcuni malintesi a livello di terminologia.

Potenziare la forza lavoro: l'approccio di OMRON allo sviluppo delle competenze nel settore manifatturiero europeo

06 Settembre 2023 Alla scoperta dell'impegno costante di OMRON nel coltivare le competenze che valorizzeranno la prossima generazione, mentre l'industria intraprende un viaggio di trasformazione per sbloccare il pieno potenziale della Quarta Rivoluzione Industriale (4IR) e che, allo stesso tempo, si muove con coraggio verso la Quinta Rivoluzione Industriale (5IR).Nelle aule del mondo accademico, nei consigli di amministrazione dei leader d'impresa più orientati al futuro e tra i politici più lungimiranti è in corso un fervente dibattito. Il tema è quello del passaggio dalla Quarta Rivoluzione Industriale, 4IR, o Industria 4.0, come viene chiamata, all'Industria 5.0, che cambierà il mondo in cui viviamo.Storicamente la rivoluzione industriale corrisponde alla prima era delle macchine, la seconda si caratterizza per l'introduzione dell'elettricità, la terza vede la diffusione dell'elettronica e la quarta si associa a Internet, come piattaforma. Ora stiamo entrando nella quinta era delle macchine, che mette in evidenza la collaborazione armoniosa uomo-macchina e il contributo dell'industria alla società. È questo il momento non solo di adattarsi, ma di guidare, di essere pionieri e di creare un futuro in cui l'innovazione non conosce limiti. Klaus Schwab, fondatore e presidente esecutivo del World Economic Forum, ha osservato che siamo sull'orlo di una rivoluzione tecnologica che cambierà radicalmente il nostro modo di vivere, lavorare e relazionarci. Nella sua scala, portata e complessità, la trasformazione sarà diversa da tutto quello che l'umanità abbia mai sperimentato prima. Il nostro mondo sta subendo una trasformazione. La produzione globale si sta evolvendo, guidata dall'automazione delle procedure industriali tradizionali attraverso la tecnologia intelligente, la comunicazione M2M e l'integrazione IoT. Questa sinergia alimenta un'automazione potenziata, una comunicazione perfetta e macchine intelligenti che analizzano e diagnosticano autonomamente le sfide.L'ascesa dell'intelligenza artificiale scatena dibattiti, alludendo a trasformazioni più profonde all'interno del nostro sistema sociale. Mentre attraversiamo questo scenario dinamico, ci prepariamo ad abbracciare l'innovazione e a rimodellare il nostro futuro.

Dai raggi X ai robot: OMRON festeggia 90 anni di innovazione

06 Giugno 2023 In occasione della Giornata del Fondatore, OMRON ha tracciato il ricordo dei suoi 90 anni di storia: in questi decenni, l'azienda si è spinta oltre i confini tecnologici e oggi confida in un futuro di innovazione dell'automazione basato su sostenibilità, digitalizzazione e collaborazione uomo-macchina.10 maggio: una data storica Il 10 maggio è probabilmente il giorno più importante del calendario OMRON. Ogni anno, in questo giorno, 30.000 dipendenti OMRON di tutto il mondo celebrano la vita e l'eredità del fondatore dell'azienda, Kazuma Tateishi. E lo fanno rinnovando il loro impegno verso la visione di Tateishi a favore dell'impiego della tecnologia per creare un mondo migliore, contribuendo al bene comune, spesso tramite la partecipazione a progetti di volontariato e beneficenza nelle proprie comunità. Traguardi nell'innovazione Il percorso di innovazione di OMRON è iniziato nel 1933 con lo sviluppo di un timer ad alta precisione per la fotografia a raggi X. Ciò ha segnato il primo contributo dell'azienda in risposta alle esigenze sociali. Nel 1960, OMRON ha presentato il primo interruttore di prossimità senza contatto al mondo, rivoluzionando le funzionalità avanzate di produzione di massa. Da allora, OMRON ha continuato a introdurre tecnologie all'avanguardia, tra cui il primo semaforo automatico, il sistema di stazioni ferroviarie senza equipaggio, il misuratore della pressione sanguigna indossabile, il controllore in logica fuzzy ultraveloce e le apparecchiature diagnostiche automatiche per cellule tumorali.

Acquisto o leasing? Come finanziare il tuo nuovo cobot

26 Aprile 2023 Uno spunto di riflessione per le PMI che devono finanziare progetti di automazioneLa carenza di competenze, la digitalizzazione, la sostenibilità e i piani di risparmio energetico stanno accelerando i progetti di automazione in molte aziende. In questi iter, una volta identificati i processi manuali che si prestano all'automazione, solitamente la domanda successiva riguarda il costo.In quest'ottica può avere senso considerare opzioni quali il leasing o il robot-as-a-service. Un esempio di strumenti che offrono alle piccole e medie imprese (PMI) una panoramica migliore degli aspetti finanziari dell'automazione è il calcolatore del ROI di OMRON. Chiunque stia prendendo in considerazione l'acquisto di un cobot o AMR può utilizzare questo strumento per scoprire il ritorno sull'investimento.

Come accelerare l'integrazione dei cobot

08 Febbraio 2023 Una buona pianificazione e solide partnership aiutano le PMI a superare gli ostacoli nell'automazione.I robot collaborativi, noti anche come cobot, godono di grande popolarità perché consentono di automatizzare attività che normalmente richiederebbero molto tempo e risorse. Attualmente si stima che il mercato globale dei robot collaborativi ammonti a circa 1,2 miliardi di dollari, con un volume di vendite che nel 2021 ha raggiunto un totale di 32.300 unità. Soprattutto ora che le aziende faticano sempre di più a trovare e mantenere dipendenti idonei, tali tecnologie sono diventate estremamente preziose in molti contesti, portando alcuni a chiedersi se i cobot siano effettivamente così costosi e in quanto tempo si possa ripagare un investimento di questo tipo.OMRON, leader dell'automazione, desidera mitigare tali preoccupazioni, in particolare per le piccole e medie imprese: soluzioni robotiche intelligenti e integrate, nonché cobot e robot mobili sono fattibili e convenienti. Per coloro che desiderano stimare il ritorno sugli investimenti, il calcolatore del ROI di OMRON offre una panoramica rapida e semplice.I cobot e i robot mobili autonomi (AMR) sono adatti sia per le PMI che per le aziende su larga scala. Eseguono attività quali trasporto, pallettizzazione, carico e scarico di macchine, assemblaggio, verniciatura o saldatura. Possono essere riattrezzati in modo rapido e flessibile e programmati anche da utenti non esperti. Il rifornimento di materiale può essere semplificato con gli AMR, mentre i cobot possono essere dedicati al carico di macchine e di processi. Tuttavia, per eseguire con successo questi progetti e accelerare l'integrazione dei robot, sono necessari know-how e partner che abbiano familiarità in questo campo. E soprattutto, i dipendenti devono essere informati e coinvolti fin dall'inizio del progetto, affinché possano prendere parte al cambiamento.Ecco alcuni suggerimenti da tenere a mente durante l'integrazione dei cobot:

Intelligenza artificiale: macchine sempre più smart

08 Febbraio 2023 Dieci anni fa ero molto orgoglioso di quanto fossero smart le macchine della nostra azienda. Ora, a fronte della definizione odierna di "smart", mi rendo conto che in realtà erano piuttosto stupide.Perché? Perché anche se stavano svolgendo la funzione per cui erano state progettate, nel momento in cui incontravano un imprevisto o un evento fuori dall'ordinario si paralizzavano. Ed erano costrette a chiedere all'operatore "qual è il mio problema?".La risoluzione dei problemi e il ripristino del funzionamento delle macchine richiedeva l'intervento di persone intelligenti. Operatori altamente qualificati. Ingegneri software e hardware esperti. Il problema è che negli ultimi dieci anni questi professionisti sono diventati sempre più introvabili. Il numero di nuovi talenti in entrata nel settore non è sufficiente a compensare il numero di lavoratori in età pensionabile. Quando lasciano l'azienda, i pensionati portano con sé la propria conoscenza duramente maturata sul campo, risultato di anni di esperienza. Per ogni lavoratore in uscita, le aziende devono fare i conti con la prospettiva di una forza lavoro meno produttiva e meno qualificata.

Che direzione prenderà il futuro, l'intralogistica? Consigli per una maggiore efficienza

15 Novembre 2022 A volte ci concentriamo così tanto sul quadro generale che dimentichiamo aspetti meno vistosi eppure molto importanti che caratterizzano la produzione intelligente. Un esempio è l'intralogistica, ossia i flussi di materiali e merci che si svolgono presso le sedi di un'azienda o in un locale di produzione. Secondo quanto emerge da un recente studio , oltre l'80% delle aziende intervistate ritiene che un maggiore utilizzo dell'intelligenza artificiale e dell'automazione nell'intralogistica sia necessario per affrontare sfide come la carenza di lavoratori qualificati o i piani di crescita.Le aziende del settore automotive che desiderano soddisfare i requisiti del mercato e dei clienti, aumentare l'efficienza e diventare più sostenibili devono sviluppare nuove idee, e i costi energetici, la crisi del gas e l'aumento dell'inflazione rendono l'impresa ancora più ardua. I concetti di Smart Factory che combinano automazione innovativa, digitalizzazione e approcci intelligenti all'intralogistica possono fornire un prezioso supporto. In questo contesto, alcuni parlano di "Industry 4.0", altri di "fabbrica del futuro", altri ancora di Industrial Internet of Things (IIoT). Tuttavia, indipendentemente dal termine utilizzato, la cosa più importante è darsi subito da fare e cercare partner affidabili. L'intralogistica è un buon punto di partenza per dare avvio al cambiamento in poco tempo. Tale urgenza è legata al fatto che numerose aziende sono al momento fortemente limitate a causa della carenza di lavoratori qualificati. Le tecnologie moderne, come i robot mobili, offrono una valida soluzione.

PPWR: perché la collaborazione tra catene, la tracciabilità e il packaging intelligente sono fondamentali

24 Settembre 2024 Secondo i dati Eurostat, nel 2021 ogni individuo residente nell'Unione europea ha prodotto 188,7 kg di imballaggi, quasi 32 kg in più rispetto al 2011. Da allora la quantità di scarti di imballaggi in plastica è aumentata del 27%. Nonostante l'incremento dei tassi di riciclaggio, un volume elevato di imballaggi di plastica non viene ancora destinato al riciclaggio: le statistiche più recenti indicano che solo una manciata di paesi europei è prossima a raggiungere un tasso di riciclaggio della plastica del 50%. Dal momento che il quadro giuridico esistente non è stato in grado di promuovere una riduzione degli scarti di imballaggio, nel 2022 la Commissione ha proposto una revisione della direttiva del 2018 del Regolamento sugli imballaggi e sui rifiuti di imballaggio (PPWR).Il PPWR rivisto dovrebbe entrare in vigore entro la fine di quest'anno e cambierà radicalmente il modo in cui l'imballaggio viene progettato, consumato e smaltito. Il regolamento aggiornato presenta un vasto ambito di applicazione, ma gli obiettivi fondamentali prevedono la riduzione della quantità di rifiuti di imballaggio generati e l'aumento della riciclabilità degli imballaggi.

Le 4 sfide principali che i produttori di veicoli elettrici devono affrontare nel loro percorso verso il raggiungimento di un futuro sostenibile