Caméras FH

Caméras de vision FH : la caméra adaptée à chaque application

Cette gamme complète de caméras de balayage de zone s'adapte à toutes les applications dans n'importe quel secteur de vision industrielle. Caméras miniatures extrêmement compactes avec éclairage intégré et ensemble complet de caméras de type C et M42 jusqu'à 21 Mpix. Elles peuvent toutes être connectées au puissant contrôleur de vision FH/FZ5 Vision, et ce en toute simplicité.

-

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.Une gamme complète de caméras pour diverses applications

FH-series Vision System Datasheet

Nouveau système de vision série FH équipé de la première fonctionnalité de détection des défauts grâce à l'IA

Fonctions

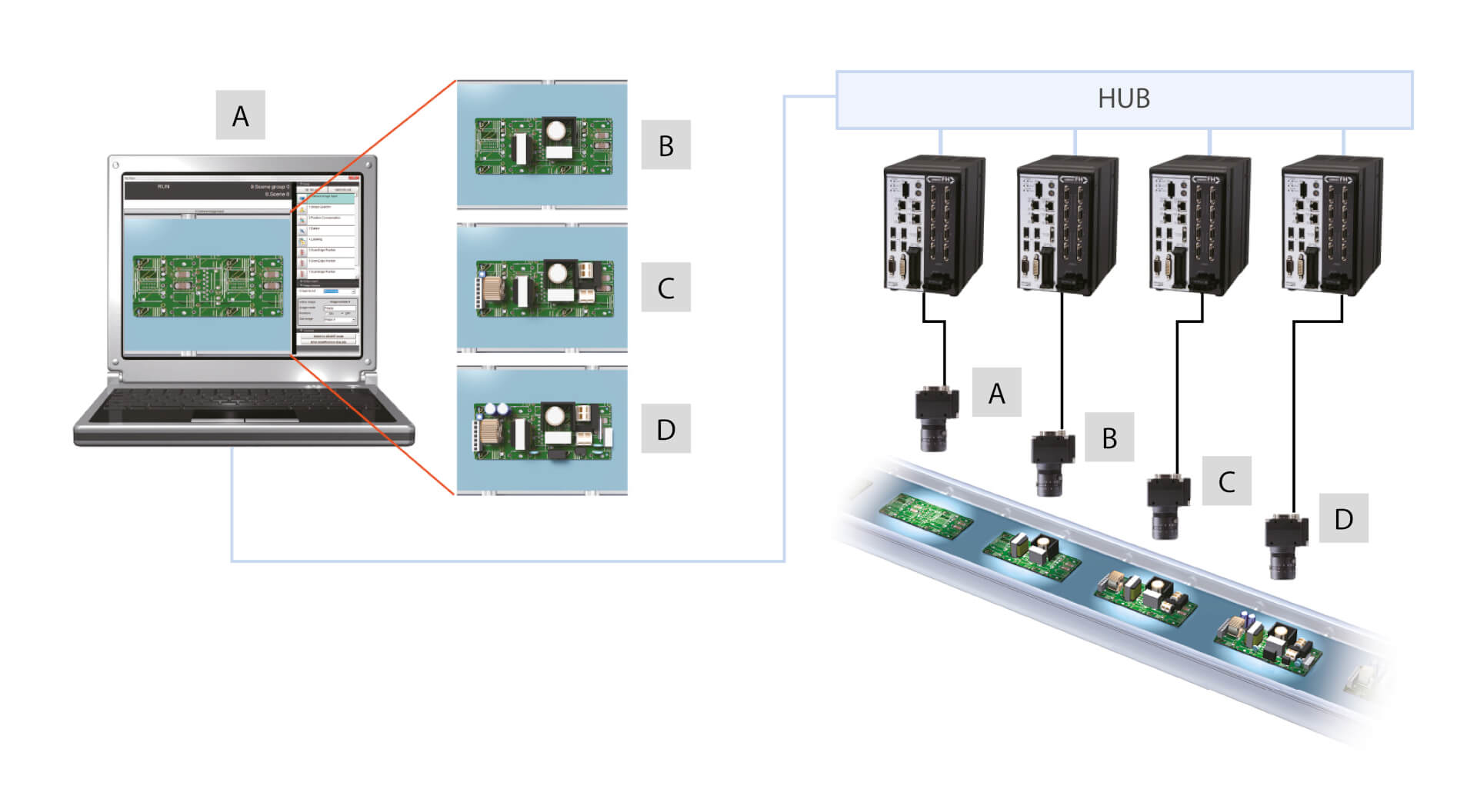

Une gamme complète de caméras pour diverses applications

Des machines plus rapides

Une intégration logicielle et matérielle en toute simplicité

Technologie de détection ultra-rapide à un format compact

Les caméras intelligentes FH/FZ sont conçues pour une utilisation dans tous les types d'inspection, de position/orientation des objets et d'opérations de mesure. Ce système de contrôleur et de caméra compact s'intègre facilement à presque toute machine ou tout robot. Fait remarquable, le système est capable d'offrir un débit de travail plus rapide et précis, vous garantissant plus d'efficacité, moins de frais et bien plus encore.

Fonctionnement optimal en ligne et hors ligne

Les connexions à un disque dur réseau ou à un ordinateur réseau offrent un large éventail de possibilités d'exploitation. Vous pouvez enregistrer des images de mesure à long terme, ou vous pouvez effectuer les vérifications et réglages sur un ordinateur sans arrêter la série FH.

Solutions d'éclairage innovantes

- La technologie d'éclairage MDMC vous permet de changer librement et en quelques millisecondes la couleur et le motif de l'orientation. Vous pouvez choisir le meilleur motif en combinant les directions d'éclairage, le RVB pleine couleur et 128 niveaux de luminosité sur 13 blocs

- Aucun échange de matériel n'est nécessaire lors des changements de produits.

- Amélioration pour une fonction d'inspection facile, rapide et fiable

- Combinaison de centaines d'éclairages en une seule unité

- Grâce à l'éclairage stéréo photométrique, votre système de vision affiche ce que l'œil humain, instrument optique le plus perfectionné, est capable de reconnaître

- Augmentation du taux d'inspection visuelle automatique pour des résultats fiables, reproductibles et productifs

- La plus robuste des solutions de vision pour inspection, même sur les surfaces extrêmement difficiles

Le système de vision FH est compatible avec les protocoles de communication les plus modernes, rapides et reconnus du secteur, ainsi que ProfiNet

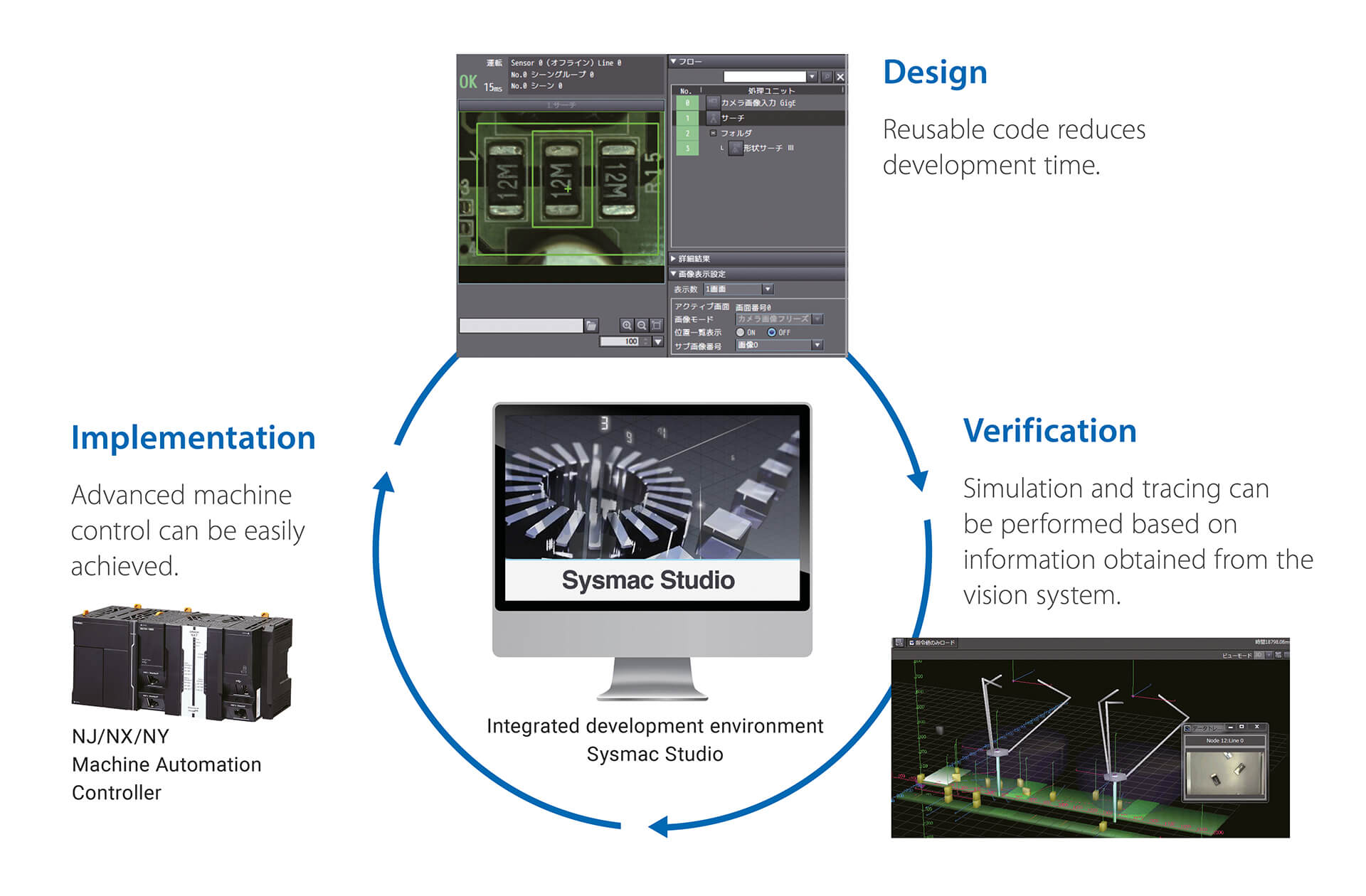

Grâce à la plate-forme Sysmac d'OMRON, l'intégration d'un système de vision dans votre machine n'a jamais été aussi simple. OMRON sait non seulement comment inspecter, déplacer et contrôler votre produit, mais également comment concevoir une solution complète adaptée à vos processus et à votre production. Qu'il s'agisse de mener une inspection ou encore de contrôler une ligne de production complète, nous vous épaulons à chaque étape et nous concentrons sur une architecture claire et compréhensible pour vous faciliter la vie et améliorer votre productivité.

-

1ConceptionLe code réutilisable réduit le temps de développement.

-

2VérificationLa simulation et la surveillance peuvent être effectuées en fonction des informations obtenues à partir du système de vision.

-

3Mise en œuvreLe contrôle avancé de la machine est facile à réaliser.

Applications

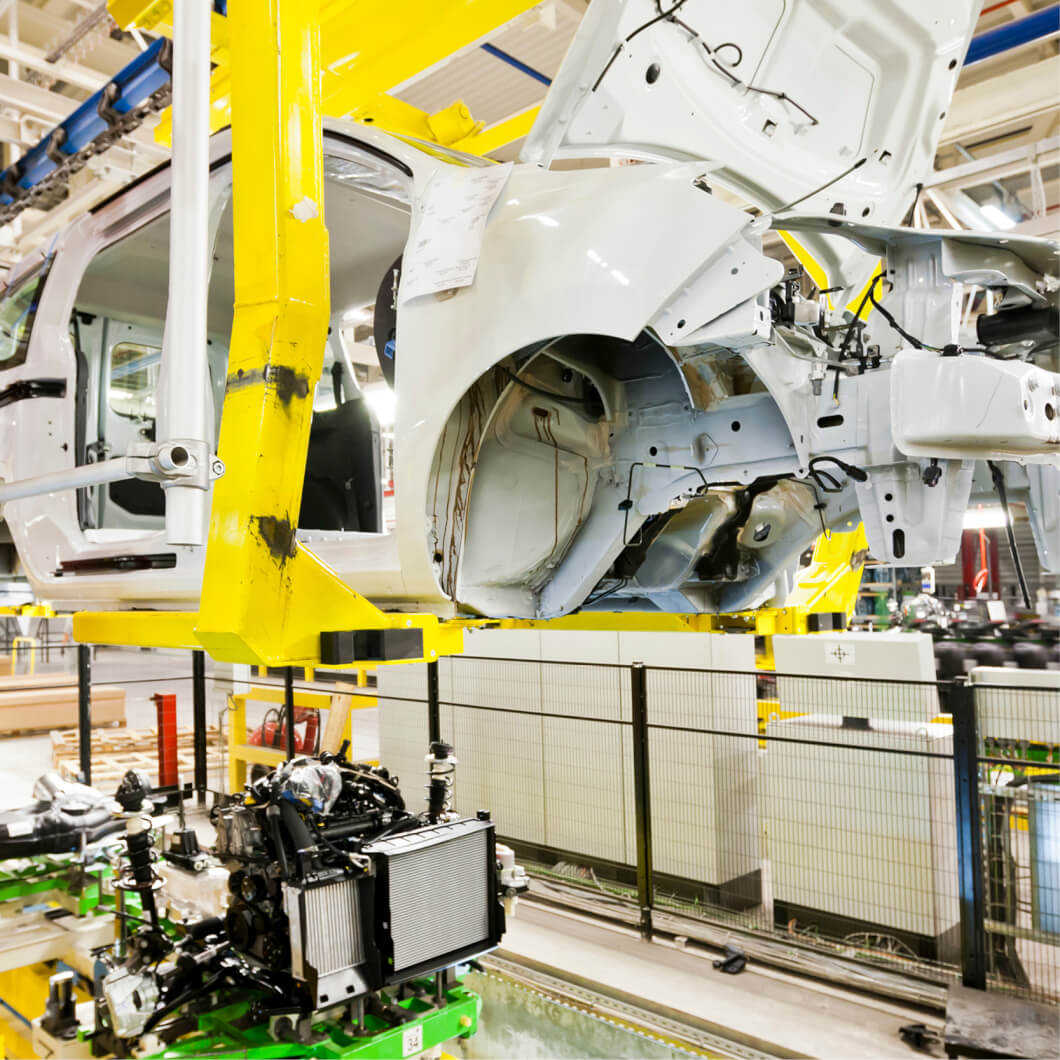

Automobile

- Lignes d'assemblage

- Lignes d'inspection de contrôle qualité

- Inspection des défauts superficiels

- Applications de mesure de haute précision

Agroalimentaire

- Contrôles de qualité

- Lignes de remplissage de liquide/poudre

- Emballage primaire et secondaire

- Mise en place

Traçabilité

- Inspection des impressions et des étiquettes

- Suivi des applications

Vidéos

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

04:37

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Caractéristiques et références

| Produit | Communication port(s) | Number of pixels | Focus distance | Autofocus | Camera family | Camera type | Frame rate | Illumination | Image width | Image height | Scan type | Shutter type | Image sensor format | Image sensor type | Lens mount | Lens type | Pixel size | Degree of protection (IP) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

2.0 MP | No | FH | Color | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x1088=2Mpix - 2/3 inch Chip - colour |

|

||

|

|

4.0 MP | No | FH | Color | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x2048Pix= 4MPix - 1 inch Chip - colour |

|

||

|

|

5.0 MP | No | FH | Color | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2592 (H) × 1944 (V)=5Mpix - 2/3 inch Chip - Farbe - Rolling Shutter |

|

||

|

|

20.4 MP | No | FH | Color | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 20,4 MP, C-Bügel, Rolling Shutter, Farbe |

|

||

|

|

0.4 MP | No | FH | Color | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 0,4 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

1.6 MP | No | FH | Color | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, colour |

|

||

|

|

3.2 MP | No | FH | Color | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, colour |

|

||

|

|

5.0 MP | No | FH | Color | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 5 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

12 MP | No | FH | Color | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH Camera, high speed, 12 MPixel, C-Mount, global shutter, color |

|

||

|

|

0.3 MP | No | FH | Monochrome | 308 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | CMOS | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard resolution FH Kamera - 640x480Pix - 1/3 inch Chip - monochrome |

|

||

|

|

2.0 MP | No | FH | Monochrome | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x1088=2Mpix - 2/3 inch Chip - monochrome |

|

||

|

|

4.0 MP | No | FH | Monochrome | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x2048Pix= 4MPix - 1 inch Chip - monochrome |

|

||

|

|

5.0 MP | No | FH | Monochrome | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2592 (H) × 1944 (V)=5Mpix - 2/3 inch Chip - Monochrom - Rolling Shutter |

|

||

|

|

20.4 MP | No | FH | Monochrome | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH Camera, high speed, 20.4 MPixel, c-Mount, rolling shutter, monochrome |

|

||

|

|

0.4 MP | No | FH | Monochrome | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 0,4 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

None | 0.3 MP | No | FH | Monochrome, SWIR | 240 fps | None | 640 pixels | 512 pixels | Area scan | Global | 1/4" | IMX991 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera, 0.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

1.6 MP | No | FH | Monochrome | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

None | 1.3 MP | No | FH | Monochrome, SWIR | 120 fps | None | 1280 pixels | 1024 pixels | Area scan | Global | 1/2" | IMX990 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera,1.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

3.2 MP | No | FH | Monochrome | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

5.0 MP | No | FH | Monochrome | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 5 MP, C-Bügel, Global Shutter, schwarzweiß |

|

||

|

|

5 MP | No | FH | Monochrome, Polarized | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH polarised camera, high speed, 5 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

12 MP | No | FH | Monochrome | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 12 MP, C-Bügel, Global Shutter, schwarzweiß |

|

||

|

|

12 MP | No | FH | Monochrome, Polarized | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH polarised camera, high speed, 12 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | 640 pixels | 480 pixels | Area scan | Global | 1/3" | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard res. Kamera - 640x480Pix - monochrom |

|

||||

|

|

2.0 MP | No | FH/FZ | Monochrome | 30 fps | 1600 pixels | 1200 pixels | Area scan | Global | 1/1.8" | C-mount | Not Applicable | 4.4 µm | IP10 | Bildverarbeitung - High Resolution Kamera - 1600x1200Pix=2MPix - 1/1.8 inch Chip - monochrom |

|

||||

|

|

5.0 MP | No | FH/FZ | Monochrome | 26.5 fps | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | C-mount | Not Applicable | 3.45 µm | IP10 | Bildverarbeitung - 5 Megapixel Kamera - Bauklein - C-Mount |

|

||||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | 640 pixels | 480 pixels | Area scan | Global | 1/3" | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard res. Kamera - 640x480Pix - color |

|

||||

|

|

2.0 MP | No | FH/FZ | Color | 30 fps | 1600 pixels | 1200 pixels | Area scan | Global | 1/1.8" | C-mount | Not Applicable | 4.4 µm | IP10 | Bildverarbeitung - High Resolution Kamera - 1600x1200Pix=2MPix - 1/1.8 inch Chip - colour |

|

||||

|

|

5.0 MP | No | FH/FZ | Color | 26.5 fps | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | C-mount | Not Applicable | 3.45 µm | IP10 | Bildverarbeitung - 5 Megapixel Color Kamera - Bauklein - C-Mount |

|

||||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Kamera - Cube-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Color-Kamera - Cube-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Kamera - Cylinder-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Color-Kamera - Cylinder-Type |

|

|||

|

|

0.3 MP | 38-60 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 7.5x4.7 bis 13x8.2mm - Abstand: 38 bis 60mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 56-215 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 13x8.2 bis 53x33mm - Abstand: 56 bis 215mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 220-970 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 53x33 bis 240x153mm - Abstand: 220 bis 970mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 32-380 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 29x18 bis 300x191mm - Abstand: 32 bis 380mm - integrierte Beleuchtung, weiß |

|

Nous proposons des possibilités de combinaisons quasi infinies pour tous les types de production.

Vous êtes intéressé ?

Contactez-moi Caméras FH

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour Caméras FH

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadTéléchargements

Produits connexes

En quoi pouvons-nous vous aider ?

Pour toute question ou demande de devis, veuillez nous contacter ou envoyer une demande.

Contactez-moi Caméras FH

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour Caméras FH

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

Download

_instruction_sheet_en.jpg)

_-_image_processing_system_instruction_sheet_en.jpg)