FH Kameras

FH-Bildverarbeitungskamera-Sortiment – die richtige Kamera für jede Anwendung

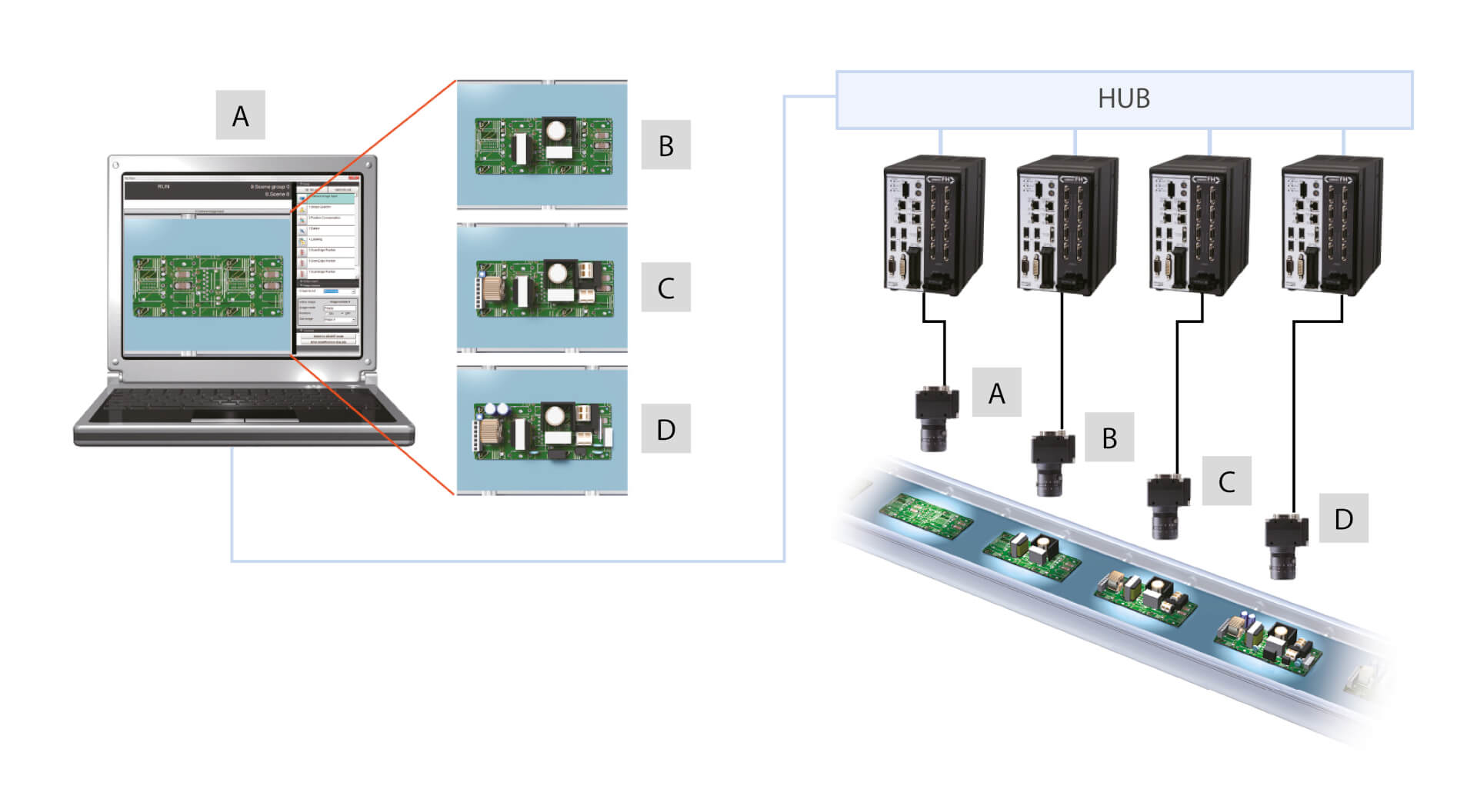

Diese Produktpalette spiegelt das gesamte Sortiment an Flächenkameras wider, um jeder Anwendung in jeder industriellen Bildverarbeitungsbranche gerecht zu werden. Extrem kompakte Miniaturkameras mit integrierter Beleuchtung und einem kompletten Satz von C- und M42-Kameras bis zu 21 MP. Alle Geräte lassen sich mit dem leistungsstarken FH/FZ5-Vision Controller verbinden – einfach anschließen und loslegen.

-

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.Ein komplettes Sortiment von Kameras für unterschiedlichste Anwendungen

FH-Bildverarbeitungssystem mit der branchenweit ersten KI-Fehlererkennung

Funktionen

Ein komplettes Sortiment von Kameras für unterschiedlichste Anwendungen

Höhere Maschinengeschwindigkeit

Einfache Integration von Soft- und Hardware

Ultra-High-Speed-Sensortechnologie in einem kompakten Design

Das System aus kompakter FH/FZ-Smart-Kamera und Steuerung ist für die Verwendung bei allen Arten von Objektprüfungs-, Positions-/Orientierungs- sowie Messaufgaben ausgelegt und lässt sich einfach in fast jede Maschine oder jeden Roboter integrieren. Das System sorgt auf einzigartige Weise für einen schnelleren und präziseren Arbeitsdurchsatz und gewährleistet so mehr Effizienz, geringere Kosten sowie einen höheren Wettbewerbsvorteil.

Innovative Beleuchtungslösungen

- Die MDMC-Beleuchtung ermöglicht es Ihnen, das Farb- und Richtungsmuster in Millisekunden beliebig zu ändern. Sie können das optimale Muster auswählen, indem Sie Beleuchtungsrichtungen mit dem vollständigen RGB-Spektrum und 128 Helligkeitsstufen in 13 Blöcken kombinieren.

- Bei Produktwechseln ist kein Austausch von Hardware-Komponenten erforderlich.

- Die Inspektionslösung, auf die Sie gewartet haben: einfach, schnell und zuverlässig

- Hunderte von Leuchten in einer Einheit

- Mit PMS-Licht erfasst Ihr Bildverarbeitungssystem, was sonst nur das intelligenteste aller optischen Instrumente erfasst – das menschliche Auge.

- Erhöhen Sie die Rate automatisierter visueller Inspektionen – zuverlässig, wiederholbar und produktiv.

- Sie erhalten die robusteste visuelle Inspektionslösung auch bei anspruchsvollsten Oberflächen.

Das FH-Bildverarbeitungssystem unterstützt die modernsten, schnellsten und verbreitetsten Industrie-Kommunikationsprotokolle – jetzt auch ProfiNet.

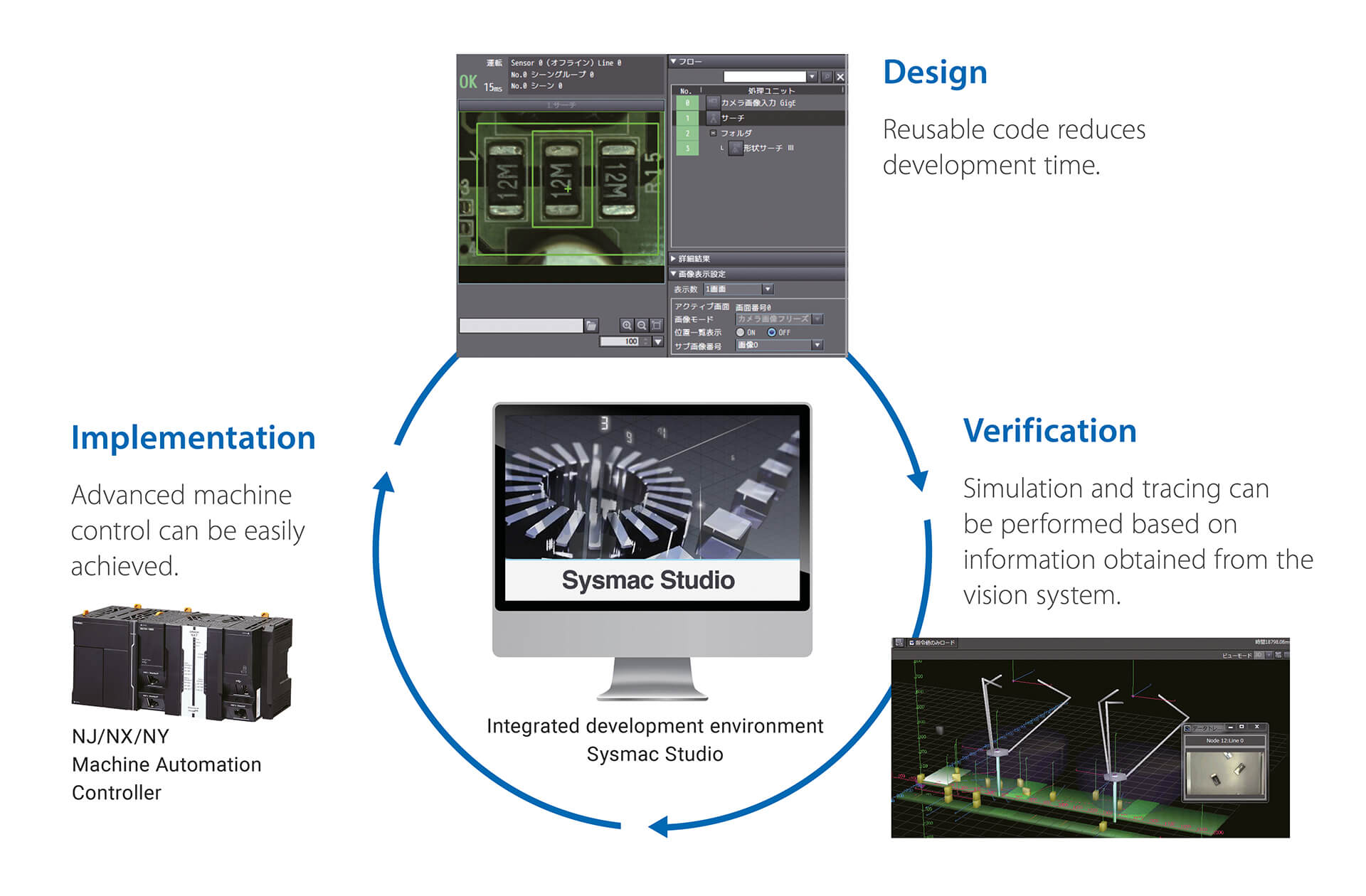

Die Integration eines Bildverarbeitungssystems in Ihre Maschine war noch nie so einfach wie mit der Sysmac-Plattform von OMRON. Wir wissen nicht nur, wie Ihr Produkt zu überprüfen ist, sondern wir können es auch verschieben, steuern und die Komplettlösung für Ihren Prozess und Ihre Produktion entwerfen. Ganz gleich, ob wir Ihnen bei der Durchführung einer einzigen Inspektion oder bei der Steuerung einer kompletten Produktionslinie helfen – bei jedem Schritt liegt unser Fokus auf einer klaren und verständlichen Architektur, die Ihr Leben einfacher macht und Ihre Produktivität steigert.

-

1DesignWiederverwendbarer Code verkürzt die Entwicklungszeit.

-

2ÜberprüfungSimulation und Rückverfolgung können auf Basis von Informationen aus dem Bildverarbeitungssystem durchgeführt werden.

-

3ImplementierungEine moderne Maschinensteuerung lässt sich leicht umsetzen.

Anwendungen

Automobilindustrie

- Montagelinien

- Inspektionslinien für die Qualitätskontrolle

- Kosmetische Inspektion

- Messanwendungen mit hoher Genauigkeit

Lebensmittel und Rohstoffe

- Qualitätsprüfung

- Abfülllinien für Flüssigkeiten/Pulver

- Primäre sekundäre Verpackung

- Pick-and-Place

Rückverfolgbarkeit

- Druck- und Etikettenprüfung

- Rück- und Nachverfolgungsanwendungen

Videos

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

04:37

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Spezifikationen & Bestellinfo

| Produkt | Communication port(s) | Number of pixels | Focus distance | Autofocus | Camera family | Camera type | Frame rate | Illumination | Image width | Image height | Scan type | Shutter type | Image sensor format | Image sensor type | Lens mount | Lens type | Pixel size | Degree of protection (IP) | Beschreibung | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

2.0 MP | No | FH | Color | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x1088=2Mpix - 2/3 inch Chip - colour |

|

||

|

|

4.0 MP | No | FH | Color | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x2048Pix= 4MPix - 1 inch Chip - colour |

|

||

|

|

5.0 MP | No | FH | Color | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2592 (H) × 1944 (V)=5Mpix - 2/3 inch Chip - Farbe - Rolling Shutter |

|

||

|

|

20.4 MP | No | FH | Color | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 20,4 MP, C-Bügel, Rolling Shutter, Farbe |

|

||

|

|

0.4 MP | No | FH | Color | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 0,4 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

1.6 MP | No | FH | Color | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, colour |

|

||

|

|

3.2 MP | No | FH | Color | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, colour |

|

||

|

|

5.0 MP | No | FH | Color | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 5 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

12 MP | No | FH | Color | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH Camera, high speed, 12 MPixel, C-Mount, global shutter, color |

|

||

|

|

0.3 MP | No | FH | Monochrome | 308 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | CMOS | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard resolution FH Kamera - 640x480Pix - 1/3 inch Chip - monochrome |

|

||

|

|

2.0 MP | No | FH | Monochrome | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x1088=2Mpix - 2/3 inch Chip - monochrome |

|

||

|

|

4.0 MP | No | FH | Monochrome | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2040x2048Pix= 4MPix - 1 inch Chip - monochrome |

|

||

|

|

5.0 MP | No | FH | Monochrome | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | Bildverarbeitung - High resolution FH Kamera - 2592 (H) × 1944 (V)=5Mpix - 2/3 inch Chip - Monochrom - Rolling Shutter |

|

||

|

|

20.4 MP | No | FH | Monochrome | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH Camera, high speed, 20.4 MPixel, c-Mount, rolling shutter, monochrome |

|

||

|

|

0.4 MP | No | FH | Monochrome | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 0,4 MP, C-Bügel, Global Shutter, Farbe |

|

||

|

|

None | 0.3 MP | No | FH | Monochrome, SWIR | 240 fps | None | 640 pixels | 512 pixels | Area scan | Global | 1/4" | IMX991 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera, 0.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

1.6 MP | No | FH | Monochrome | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

None | 1.3 MP | No | FH | Monochrome, SWIR | 120 fps | None | 1280 pixels | 1024 pixels | Area scan | Global | 1/2" | IMX990 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera,1.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

3.2 MP | No | FH | Monochrome | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

5.0 MP | No | FH | Monochrome | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 5 MP, C-Bügel, Global Shutter, schwarzweiß |

|

||

|

|

5 MP | No | FH | Monochrome, Polarised | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH polarised camera, high speed, 5 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

12 MP | No | FH | Monochrome | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH-Kamera, hohe Geschwindigkeit, 12 MP, C-Bügel, Global Shutter, schwarzweiß |

|

||

|

|

12 MP | No | FH | Monochrome, Polarised | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH polarised camera, high speed, 12 MPixel, C-Mount, global shutter, monochrome |

|

||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | 640 pixels | 480 pixels | Area scan | Global | 1/3" | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard res. Kamera - 640x480Pix - monochrom |

|

||||

|

|

2.0 MP | No | FH/FZ | Monochrome | 30 fps | 1600 pixels | 1200 pixels | Area scan | Global | 1/1.8" | C-mount | Not Applicable | 4.4 µm | IP10 | Bildverarbeitung - High Resolution Kamera - 1600x1200Pix=2MPix - 1/1.8 inch Chip - monochrom |

|

||||

|

|

5.0 MP | No | FH/FZ | Monochrome | 26.5 fps | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | C-mount | Not Applicable | 3.45 µm | IP10 | Bildverarbeitung - 5 Megapixel Kamera - Bauklein - C-Mount |

|

||||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | 640 pixels | 480 pixels | Area scan | Global | 1/3" | C-mount | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Standard res. Kamera - 640x480Pix - color |

|

||||

|

|

2.0 MP | No | FH/FZ | Color | 30 fps | 1600 pixels | 1200 pixels | Area scan | Global | 1/1.8" | C-mount | Not Applicable | 4.4 µm | IP10 | Bildverarbeitung - High Resolution Kamera - 1600x1200Pix=2MPix - 1/1.8 inch Chip - colour |

|

||||

|

|

5.0 MP | No | FH/FZ | Color | 26.5 fps | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | C-mount | Not Applicable | 3.45 µm | IP10 | Bildverarbeitung - 5 Megapixel Color Kamera - Bauklein - C-Mount |

|

||||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Kamera - Cube-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Color-Kamera - Cube-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Monochrome | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Kamera - Cylinder-Type |

|

|||

|

|

0.3 MP | No | FH/FZ | Color | 80 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | M10.5x0.5 | Not Applicable | 7.4 µm | IP10 | Bildverarbeitung - Micro-Color-Kamera - Cylinder-Type |

|

|||

|

|

0.3 MP | 38-60 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 7.5x4.7 bis 13x8.2mm - Abstand: 38 bis 60mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 56-215 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 13x8.2 bis 53x33mm - Abstand: 56 bis 215mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 220-970 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 53x33 bis 240x153mm - Abstand: 220 bis 970mm - integrierte Beleuchtung, weiß |

|

||||

|

|

0.3 MP | 32-380 mm | No | FH/FZ | Color | 60 fps | 752 pixels | 480 pixels | Area scan | Global | 1/3" | None | 6.0 µm | IP10 | Bildverarbeitung - Farbkamera für FZ Systeme - Erfassungsb.: 29x18 bis 300x191mm - Abstand: 32 bis 380mm - integrierte Beleuchtung, weiß |

|

Wir haben nahezu unbegrenzte Kombinationsmöglichkeiten, um allen Produktionsanforderungen gerecht zu werden.

Haben wir Ihr Interesse geweckt?

Ihr Kontakt FH Kameras

Vielen Dank für Ihre Anfrage. Wir setzen uns umgehend mit Ihnen in Verbindung.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

DownloadAngebot für FH Kameras

Über dieses Formular erhalten Sie ein Angebot zu Ihrem ausgewählten Produkt. Bitte füllen Sie alle Felder aus, die diese * Markierung besitzen. Ihre persönlichen Daten werden natürlich vertraulich behandelt.

Vielen Dank für Ihre Angebots-Anfrage, die wir schnellstmöglich beantworten werden.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

DownloadDownloads

Verwandte Produkte

Wie können wir Ihnen helfen?

Wenn Sie eine Frage haben oder ein Angebot anfordern möchten, kontaktieren Sie uns oder senden Sie eine Anfrage.

Ihr Kontakt FH Kameras

Vielen Dank für Ihre Anfrage. Wir setzen uns umgehend mit Ihnen in Verbindung.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

DownloadAngebot für FH Kameras

Über dieses Formular erhalten Sie ein Angebot zu Ihrem ausgewählten Produkt. Bitte füllen Sie alle Felder aus, die diese * Markierung besitzen. Ihre persönlichen Daten werden natürlich vertraulich behandelt.

Vielen Dank für Ihre Angebots-Anfrage, die wir schnellstmöglich beantworten werden.

Es liegen zur Zeit technische Probleme vor. Ihre Übertragung war nicht erfolgreich. Entschuldigen Sie dies bitte und versuchen es später noch einmal. Details

Download

_instruction_sheet_en.jpg)

_-_image_processing_system_instruction_sheet_en.jpg)