TM

Conçu pour l'avenir de l'automatisation

- Permet de créer un lieu de travail sûr et harmonieux entre les humains et les machines.

- 31 fonctions de sécurité, respect des normes ISO 13849-1, Cat.3, PLd, certifiées.

- Conformité totale à la norme ISO 10218-1.

- Environnement de programmation graphique facile à utiliser pour un démarrage et un fonctionnement rapides.

- Basé sur la vision, le contrôle intégré du robot permet d'effectuer des opérations d'asservissement, d'inspection et de mesure visuelles.

- La caméra et le repère en option permettent un véritable changement rapide et flexible.

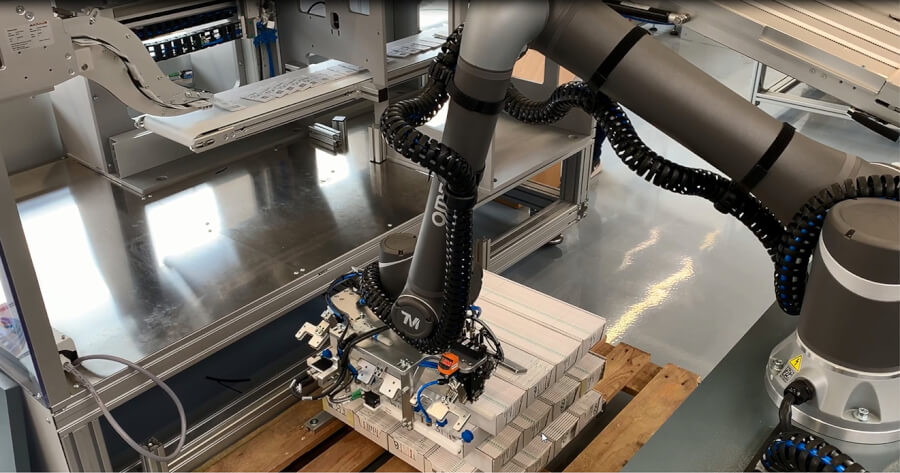

- La capacité d'intégration avec les robots mobiles permet de bénéficier d'applications de manutention de machines et de logistique entièrement autonomes.

- Modèles de bus de terrain, y compris Ethernet/IP et Profinet.

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!Le robot collaboratif

Omron TM12 cobot automates booklet feeding for Kraus Maschinenbau

Cobots streamline processes in medtech and packaging industry

Fonctions

Configuration plus rapide grâce à la vision intégrée

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Démarrage et changement rapide

Sécurité dans les applications collaboratives

Cobot Safety Article d'expert

Cobot et production flexible: pérenniser des PME ?

De nombreux pays d'Europe, comme le Royaume-Uni et l'Allemagne, risquent de connaître de graves pénuries de main-d'œuvre au cours de la prochaine décennie, en particulier en ce qui concerne les spécialistes techniques. Par ailleurs, le cycle de vie des produits est de plus en plus court. Malgré cela, les petites et moyennes entreprises (PME) peuvent être réticentes à investir dans un processus d'automatisation supplémentaire. Pourtant, les robots collaboratifs (cobots) sont faciles à installer et offrent une solution rapide et économique. Ils sont capables d'accroître la flexibilité, la qualité et la vitesse de production et permettent aux entreprises de réagir rapidement à l'évolution des conditions du marché. Les cobots de la série TM d'Omron illustrent parfaitement cette polyvalence.

Modèles

TM5S

- Portée (mm) : 900

- Charge utile maximale (kg) : 5

- Vitesse maximale (m/s) : 1,4

TM7S

- Portée (mm) : 700

- Charge utile maximale (kg) : 7

- Vitesse maximale (m/s) : 1,1

TM12S

- Portée (mm) : 1 300

- Charge utile maximale (kg) : 12

- Vitesse maximale (m/s) : 1,3

TM14S

- Portée (mm) : 1 100

- Charge utile maximale (kg) : 14

- Vitesse maximale (m/s) : 1,1

TM 5 – 700

- Portée (mm) : 700

- Charge utile maximale (kg) : 6

- Vitesse maximale (m/s) : 1,1

TM 5 – 900

- Portée (mm) : 900

- Charge utile maximale (kg) : 4

- Vitesse maximale (m/s) : 1,4

TM12

- Portée (mm) : 1 300

- Charge utile maximale (kg) : 12

- Vitesse maximale (m/s) : 1,3

TM14

- Portée (mm) : 1 100

- Charge utile maximale (kg) : 14

- Vitesse maximale (m/s) : 1,1

TM 16

- Portée (mm) : 900

- Charge utile maximale (kg) : 16

- Vitesse maximale (m/s) : 1,1

TM20

- Portée (mm) : 1 300

- Charge utile maximale (kg) : 20

- Vitesse maximale (m/s) : 1,3

Caractéristiques et références

| Produit | Hardware version | Payload | Reach | PROFINET communication | EtherNet/IP communication | Vision | Power supply type | SEMI S2 certified | Food grade grease | SIL according to IEC 61508 | Performance level according to EN ISO 13849-1 | Cable length | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-900 (model without camera), HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-900 (model without camera), 12 m cable, HW3.2 |

|

Nous proposons des possibilités de combinaisons quasi infinies pour tous les types de production.

Vous êtes intéressé ?

Contactez-moi TM

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour TM

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadCas client

Les cobots offrent un avantage concurrentiel au fabricant d'engrenages

Fischer Gears, un fabricant danois d'engrenages, a stimulé la compétitivité de son processus de production, notamment pour les gammes plus importantes, en installant deux robots TM d'Omron. Les robots collaboratifs (cobots) permettent aux employés expérimentés de se consacrer à des tâches à plus forte valeur ajoutée.

Une application cobot innovante améliore la sécurité chez Leica Geosystems

Un robot collaboratif automatise la manipulation des plateaux et améliore la sécurité et l'ergonomie dans une zone de travail dangereuse.

Les robots collaboratifs améliorent la productivité chez CLECA

Processus de palettisation automatisé avec les cobots OMRON TM12

La solution de palettisation de Reitec répond aux besoins des clients du secteur des biens de consommation courante

OMRON et Reitec se sont associés pour créer le nouveau cobot de palettisation RC-1

Cobot de palettisation agile de Reeco Automation

Encombrement réduit de 60 % et jusqu'à 50 % moins cher que les robots de palettisation traditionnels

Traçabilité 4.0 grâce à un étiquetage simplifié des emballages et des cobots

Un robot collaboratif effectue un étiquetage intelligent sur différents formats de produits, réduisant ainsi les temps d'arrêt dus aux changements de format jusqu'à 70 %, grâce à une solution développée par Bluengineering pour Gruppo Romani, en Italie.

Cisel garantit la traçabilité, la sécurité et la qualité en testant les cartes de circuits imprimés à l'aide d'un cobot

Cisel est une société italienne spécialisée dans la conception et la production de cartes de circuits imprimés flexibles pour les industries de l'automobile, du génie civil et de la fabrication. La société a récemment choisi un robot collaboratif OMRON TM5 (cobot) pour automatiser les tests électriques des cartes utilisées dans le système de direction assistée d'un fabricant automobile leader du marché.

Un cobot garantit des aimants parfaitement assemblés sur les bouchons de vidange LITMAT

Les robots collaboratifs (cobots) sont de plus en plus utilisés dans de nombreux secteurs et applications. Ils peuvent réellement faire la différence en termes d'efficacité et de productivité dans le cycle de production. LITMAT SpA est l'une des entreprises qui bénéficient de ces avantages.

Unika choisit Landmark pour amener ses niveaux de qualité vers de nouveaux sommets

Les cobots OMRON TM avec système de vision intégrée éliminent les erreurs humaines et augmentent l'efficacité de la production

Applications

Solutions

Solution de manipulateur mobile OMRON

Solution hybride cobot et robot mobile unique d'OMRON

Solution de palettisation cobot

Logiciel OMRON API Sysmac basé sur « FB »

Tutoriels vidéo

-

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

00:31

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

-

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

06:34

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

-

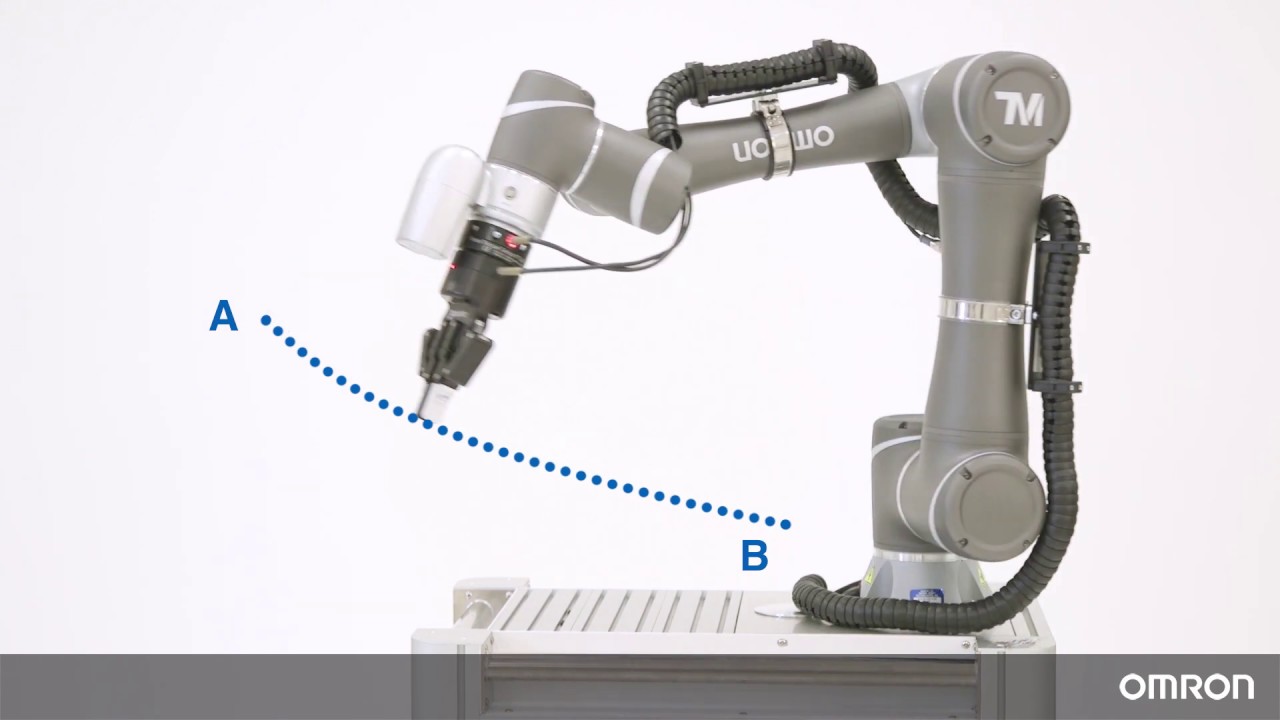

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

06:40

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

-

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

05:23

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

-

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

04:37

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

-

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

05:13

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

-

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

06:46

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

-

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

04:49

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

-

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

07:15

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

-

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

04:32

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

-

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

05:50

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

-

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

06:55

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.Téléchargements

Services

En quoi pouvons-nous vous aider ?

Pour toute question ou demande de devis, veuillez nous contacter ou envoyer une demande.

Contactez-moi TM

Merci de votre demande. Nous reviendrons vers vous dès que possible.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

DownloadDevis pour TM

Vous pouvez utiliser ce formulaire pour demander un devis sur le produit de votre choix. Merci de compléter tous les champs *. Les informations sont traitées de manière confidentielle.

Merci de votre demande. Nous vous enverrons l'information demandée au plus tôt.

Nous rencontrons des problèmes techniques. Votre demande ne peut être traitée. Veuillez nous excuser et ré-essayer plus tard. Détails :

Download